Product Description

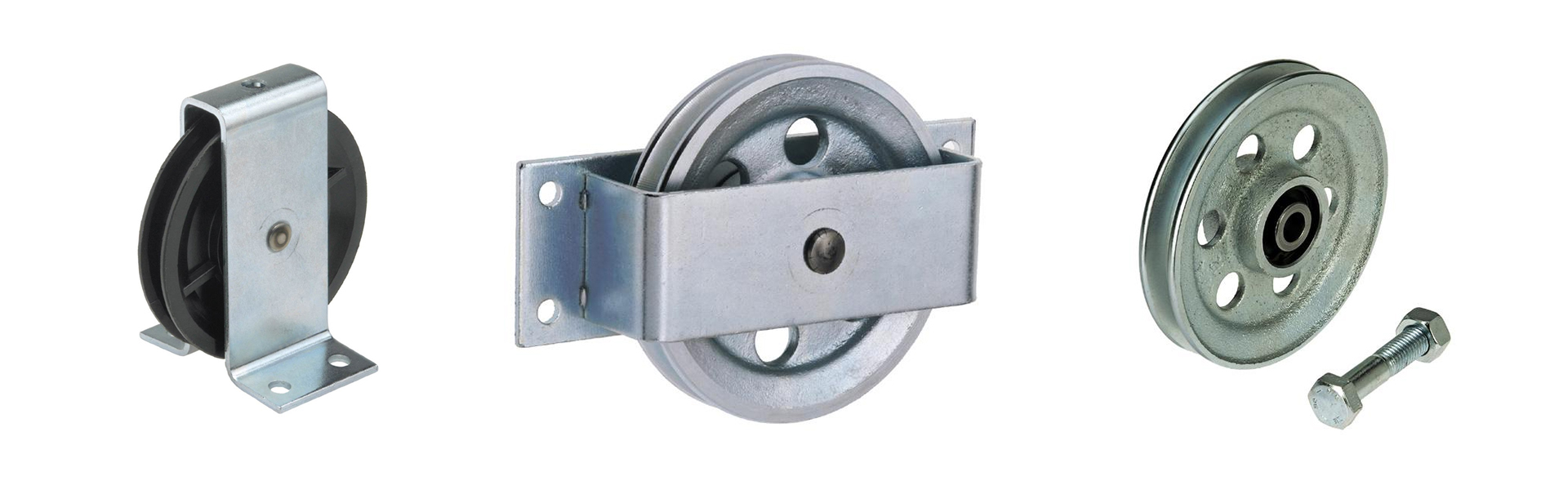

Detailed Photos

Description of ceramic guide pulley(Ceramic wire roller) :

Product Description

The ceramic wire guide pulley (wire roller) is used for the direction change and the guidance of the enameled wire. The ceramic circle inside is made by the fine porcelain. There is a high-speed bearing in the ceramic circle which can assure the lag sliding distance between the wire and the circle is no more than 0.2mm, thus the wire insulation film has been protected and the beating of the wire has been controlled within a certain small scope in good. The sidewalls of the ceramic roller can prevent the jump of the wire during the winding, and stabilized the tension.

Features of ceramic guide pulley(Ceramic wire roller):

1.The surface polish degree of the porcelain ring : Ra0.2.

2.The sliding distance between enameled wire and the roller :≤0.2mm

3.The hardness : HRa88.

| No. |

A (mm ) |

B(mm) |

C(mm) |

H(mm) |

| CR001 |

9.9 |

8 |

2 |

4 |

| CR002 |

10.1 |

|||

| CR003 |

11.5 |

10 |

4 |

4 |

| CR004 |

13.9 |

10 |

3 |

6 |

| CR005 |

7.8 |

6 |

2 |

3.2 |

| CR006 |

10.6 |

7.3 |

2 |

3.5 |

| CR007 |

27 |

15 |

5 |

11 |

| CR008 |

16.5 |

13 |

4 |

5 |

Our Services

Service tenet

Provide you the best service with “fast + satisfactory + safe”.

Warranty period

12 months long after the user received the product.

Warranty items

Only for abnormal breakdown caused by the machine design or manufacture defect,

free repair and accessory will be provided.

Technology service ability

All service engineers with many years experience are gotten special technology training, who can deal with various breakdown problem.

Xihu (West Lake) Dis. the user to use accurately and how to maintain the product.

Provide free consultation about production process technology of electronic products.

Service after sell

In order to guarantee the machine used normally, we’d have training on how to operate, use and maintain our product by English manual, video, guiding on line.

Use instruction

Apply for the right complete size of product, otherwise, the wrong dimensions will affect the use effect.

Do ensure using the product accord to the use instruction completely.Do not exceed the scope of application of the products.

Maintain the product after use,Damp proof, rust proof, leak proof, explosion-proof, regular maintenance and inspection should

be taken care. All done help to extend the use period.

User document management

Establish perfect user document management in EPR system, Every product running details would be followed to manage. The users would be taken good care.

About product

1. Product photo: All product photos are taken by real product, There is the color aberration between the product and photo, which is caused by shoot light, product size, manual technology and computer display etc. It’s not quality problem. Parts of products are changed in appearance due to technology revolutionary and process improvement. SanShine would ensure the parameter of product is unchanged, The product couldn’t affect to use.

2.Product size: All parameters are all measured by manual just for reference. There is a small deviation due to the difference of measure tools, lot products and produce process. Real size should be accordance with the final delivery product.

3.Quality inspection: All products should be inspected strictly before shipment. Ensure the good function and appearance.

Packaging & Shipping

Package and transport

General package(Paper carton or plastic bag): For small goods, Package it with form and pack paper to guarantee unbroken during the transport.

Wooden case package: For larger scale goods as machine equipment etc, we have special skilled carpenter, who would make the proper wooden case with exact thickness,density,length. The up arrow ↑marked on the outer wooden case. Buffer material would be put in the wooden case to prevent crack and shock. We will inform you the delivery note. You just need to wait for phone call, then pick up the goods at the nearest logistic station .(Please let me know in advance if you want get the goods at home.)

Our Customers

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| The Surface Polish Degree of The Porcela: | Ra0.2. |

|---|---|

| The Sliding Distance Between Enameled Wi: | ≤0.2mm |

| The Hardness: | Hra88. |

| Size: | See The Details |

| Transport Package: | Good Packing in The Cartons |

| Specification: | More Models (Refer The List) |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is the role of wire pulleys in maintaining proper tension in cable-based systems?

Wire pulleys play a crucial role in maintaining proper tension in cable-based systems. They help distribute and manage the tension in the cables, ensuring smooth and efficient operation. Here’s a detailed explanation of the role of wire pulleys in maintaining proper tension:

1. Load Distribution:

Wire pulleys help distribute the load evenly across the cables in a system. As the cables pass over the pulleys, they change direction, which spreads the tension along the length of the cables. This prevents excessive stress and strain on any specific section of the cables, promoting uniform tension distribution.

2. Directional Change:

Wire pulleys facilitate changes in the direction of the cables. By redirecting the cables, pulleys allow for efficient routing and alignment, ensuring that the cables follow the desired path. This is particularly important in complex cable-based systems where cables need to navigate around obstacles or change directions at different points.

3. Tension Adjustment:

Wire pulleys enable tension adjustment in cable-based systems. By altering the position of the pulleys or changing the number of pulleys in the system, the tension in the cables can be adjusted as needed. This flexibility allows for fine-tuning the tension to achieve optimal performance and stability in the system.

4. Cable Retention:

Wire pulleys help retain the cables in their proper position. The grooved or contoured surface of the pulleys prevents the cables from slipping or coming off their intended path. This is particularly important in applications where maintaining cable alignment and position is critical for the system’s functionality and safety.

5. Friction Reduction:

Well-designed wire pulleys minimize friction between the cables and the pulley surfaces. Reduced friction helps to prevent excessive wear on the cables and reduces the energy required to move the cables. This results in smoother operation, lower power consumption, and less strain on the entire cable-based system.

6. Cable Protection:

Wire pulleys provide protection to the cables from external elements. The pulley’s smooth and rounded surfaces prevent sharp bends or kinks in the cables, reducing the risk of cable damage or fatigue. Additionally, pulleys can be designed with coatings or materials that offer resistance to corrosion, abrasion, or chemical exposure, further safeguarding the cables.

7. System Stability:

By maintaining proper tension in the cables, wire pulleys contribute to the overall stability of the cable-based system. Balanced tension prevents slack or excessive stretching of the cables, ensuring that they maintain the desired position and alignment. This stability is crucial for the system’s performance, reliability, and safety.

It is important to select wire pulleys that are appropriately sized, rated for the intended load, and compatible with the cable diameter and construction. Regular maintenance and inspection of the pulleys are also necessary to ensure they remain in good working condition and continue to perform their role effectively.

By utilizing properly designed and installed wire pulleys, cable-based systems can maintain optimal tension, promoting efficient operation, longevity of cables, and overall system reliability.

What safety precautions should be taken when using wire pulleys for heavy lifting?

When using wire pulleys for heavy lifting, it is crucial to follow specific safety precautions to prevent accidents, injuries, and damage. Here are some important safety measures to consider:

1. Equipment Inspection:

Prior to using wire pulleys, conduct a thorough inspection of all equipment involved, including the pulleys, ropes or cables, hooks, and attachments. Check for any signs of wear, damage, or deterioration. Ensure that all components are in good working condition and properly rated for the intended load.

2. Load Capacity:

Never exceed the maximum load capacity specified by the manufacturer for the wire pulleys and associated equipment. Determine the weight of the load accurately and select the appropriate pulley with the necessary load rating to ensure safe lifting operations.

3. Proper Installation:

Follow the manufacturer’s instructions for the correct installation of wire pulleys. Ensure that they are securely attached to stable anchor points or support structures capable of withstanding the load. Use appropriate fittings, connectors, and fasteners that are compatible with the pulley and the lifting system.

4. Rigging Techniques:

Use proper rigging techniques to attach the load to the wire pulley. Ensure that the load is properly balanced and securely attached to prevent shifting, slipping, or falling during lifting. Use appropriate slings, hooks, or other rigging hardware that are suitable for the load and compatible with the pulley.

5. Personal Protective Equipment (PPE):

Wear the necessary personal protective equipment, such as gloves, safety glasses, and hard hats, when operating wire pulleys for heavy lifting. PPE helps protect against potential hazards, such as hand injuries, impact hazards, or falling objects.

6. Communication:

Establish clear communication protocols between the operator and other personnel involved in the lifting operation. Use standardized hand signals or communication devices to ensure effective communication and coordination during the lifting process.

7. Clear Work Area:

Clear the work area of any obstacles, debris, or personnel who are not directly involved in the lifting operation. Ensure that there is sufficient space for the load to move vertically or horizontally without interference. Mark off the work area and restrict access to unauthorized personnel.

8. Operator Training:

Ensure that operators are properly trained and competent in using wire pulleys for heavy lifting. Training should cover equipment operation, safe lifting practices, load calculation, inspection procedures, and emergency protocols. Regularly update training to stay informed about the latest safety guidelines and best practices.

9. Regular Maintenance:

Schedule regular maintenance and inspections of wire pulleys and lifting equipment. Follow the manufacturer’s recommendations for lubrication, cleaning, and replacement of worn or damaged components. Promptly address any identified issues or concerns.

10. Emergency Preparedness:

Develop and communicate emergency procedures in case of accidents, equipment failure, or unexpected incidents during heavy lifting operations. Ensure that personnel are familiar with emergency shutdown procedures, evacuation routes, and the location of emergency equipment, such as fire extinguishers or first aid kits.

By adhering to these safety precautions, you can minimize the risks associated with using wire pulleys for heavy lifting and promote a safe working environment for all personnel involved.

Can you explain the fundamental principles of how wire pulleys work?

Wire pulleys operate based on a few fundamental principles that enable their functionality. Here’s an explanation of these principles:

1. Mechanical Advantage:

The primary principle behind wire pulleys is mechanical advantage. By using a pulley system, the force required to move a load can be reduced. When a wire or cable is looped around a pulley, the tension in the wire is distributed between the sections of wire on either side of the pulley. This distribution of tension allows the force applied to one side of the pulley to be multiplied on the other side, resulting in a mechanical advantage. The mechanical advantage depends on the number of pulleys in the system and the configuration of the pulleys, such as whether they are fixed or movable.

2. Friction Reduction:

Wire pulleys are designed to minimize friction between the wire or cable and the pulley itself. The pulley’s grooved wheel or sheave provides a smooth surface for the wire to pass over, reducing the resistance caused by friction. By minimizing friction, the pulley enables the wire to move more easily, requiring less force and effort to operate. Additionally, high-quality pulleys often incorporate bearings or bushings to further reduce friction and ensure smooth movement.

3. Directional Change:

Another principle of wire pulleys is directional change. A wire pulley allows the wire or cable to change its direction of movement. When the wire is pulled in one direction, it wraps around the pulley’s grooved wheel, changing its path. This change in direction is useful in various applications where the wire needs to be redirected or guided along a specific path. The pulley’s design ensures that the wire remains properly aligned and in contact with the grooved wheel, preventing it from slipping off during operation.

4. Load Distribution:

Wire pulleys also play a role in load distribution. When a load is suspended by a wire or cable passing over a pulley, the weight of the load is distributed between the sections of wire on either side of the pulley. This distribution of the load helps to balance the forces acting on the pulley system, reducing strain on the wire and ensuring stability during operation. Proper load distribution is crucial to prevent overloading the wire and pulley system, which could lead to failure or damage.

5. Tension Management:

Tension management is an important principle in wire pulley systems. The pulley helps manage and distribute tension along the wire or cable. By adjusting the configuration of the pulleys, tension can be controlled and balanced throughout the system. Proper tension management is essential for maintaining the stability and efficiency of the pulley system, preventing slack or excessive tension that may affect performance or safety.

By leveraging these fundamental principles, wire pulleys enable the smooth movement, force multiplication, directional change, load distribution, and tension management of wires or cables in various applications.

editor by CX

2024-04-16