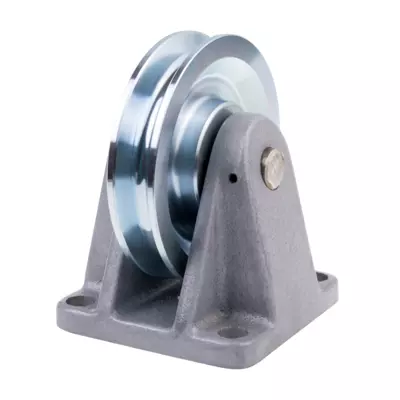

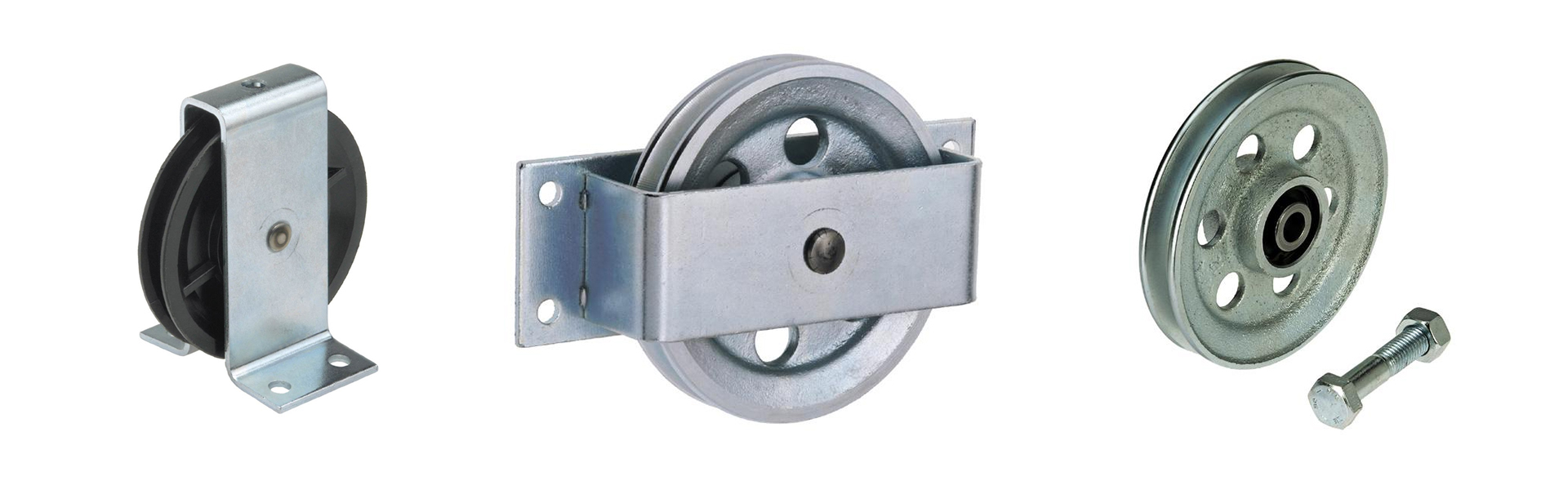

Product Description

Multi Groove Leading Pulley For Wire and Cable

Application

Leading pulley use for traction of cables ,mainly used in extrusion line.

Features

1.Provide leading pulleys of various sizes, up to 3000mm.

2.There are no sand holes in the groove, or a small amount of sand holes.

3.Provide surface treatment such as anodic and porcelain spraying.

Specification

| Part Name | Model | Bearing |

| Ф255*55 | Ф255*55 | Ф14 |

| Ф300*74 | Ф300*74 | Ф35 |

| Ф300*94 | Ф300*94 | Ф35 |

| Ф350*94 | Ф350*94 | Ф35 |

| Ф350*102 | Ф350*102 | Ф40 |

| Ф400*94 | Ф400*94 | Ф35 |

| Ф400*105 | Ф400*105 | Ф40 |

| Ф400*118 | Ф400*118 | Ф40 |

| Ф450*105 | Ф450*105 | Ф40 |

| Ф450*116 | Ф450*116 | Ф40 |

| Ф500*100 | Ф500*100 | Ф38 |

| Ф500*116 | Ф500*116 | Ф40 |

| Ф500*105 | Ф500*105 | Ф40 |

| Ф500*89 | Ф500*89 | Ф35 |

| Ф605*126 | Ф605*126 | Ф50 |

| Ф600*105 | Ф600*105 | Ф40 |

| Ф600*116 | Ф600*116 | Ф40 |

| Ф600*136 | Ф600*136 | Ф40 |

| Ф686*170 | Ф686*170 | Ф50 |

| Ф686*212 | Ф686*212 | Ф50 |

| Ф800*155 | Ф800*155 | Ф50 |

| Ф800*100 | Ф800*100 | Ф50 |

| Ф800*130 | Ф800*130 | Ф50 |

Products picture

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Certification: | RoHS |

| Standard: | GB |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the quality and precision of wire pulleys affect their performance?

The quality and precision of wire pulleys have a significant impact on their performance in lifting and pulling tasks. Here’s how the quality and precision of wire pulleys affect their performance:

1. Load Capacity:

High-quality wire pulleys are designed and manufactured to withstand specified load capacities. They undergo rigorous testing to ensure they can handle the intended loads safely. A pulley with accurate load capacity information allows operators to select the appropriate pulley for their specific lifting or pulling task, preventing overloading and potential equipment failure.

2. Durability:

Quality wire pulleys are constructed using robust materials and precise manufacturing processes. This enhances their durability, allowing them to withstand repeated use, heavy loads, and harsh operating conditions. A durable pulley resists wear, corrosion, and deformation, ensuring reliable performance and extending its service life.

3. Efficiency:

Precision engineering and manufacturing of wire pulleys contribute to their efficiency during lifting and pulling operations. High-quality pulleys are designed to minimize friction, which reduces energy loss and facilitates smoother movement of the load. This improves the overall efficiency of the lifting system, requiring less force or power input to achieve the desired results.

4. Smooth Operation:

Quality wire pulleys are manufactured with precise dimensions and tolerances. This results in smooth operation and reduced friction between the pulley and the rope or cable. Smooth operation minimizes wear on the rope or cable, reduces the risk of snags or jams, and ensures consistent and predictable movement of the load.

5. Safety:

High-quality wire pulleys undergo stringent quality control measures to ensure they meet safety standards and regulations. They are designed with features such as accurate load ratings, safety factor considerations, and appropriate certifications. A pulley with reliable safety features reduces the risk of accidents, equipment failure, and injuries during lifting or pulling operations.

6. Noise and Vibration:

Precision manufacturing of wire pulleys helps to minimize noise and vibration during operation. Well-balanced pulleys with accurate alignment and smooth rotation produce less noise and vibration, creating a quieter and more comfortable working environment for operators.

7. Compatibility:

Quality wire pulleys are designed to be compatible with various lifting systems, ropes, or cables. Precise dimensions and standardized interfaces ensure that the pulleys can be easily integrated into existing equipment or rigging setups. This provides flexibility and convenience when selecting and using wire pulleys in different applications.

When choosing wire pulleys, it is important to consider the reputation and reliability of the manufacturer or supplier. Trusted manufacturers with a track record of producing high-quality pulleys are more likely to deliver products that meet or exceed performance expectations.

By prioritizing quality and precision in wire pulleys, you can expect improved performance, increased safety, enhanced durability, and optimal efficiency in your lifting and pulling operations.

What safety precautions should be taken when using wire pulleys for heavy lifting?

When using wire pulleys for heavy lifting, it is crucial to follow specific safety precautions to prevent accidents, injuries, and damage. Here are some important safety measures to consider:

1. Equipment Inspection:

Prior to using wire pulleys, conduct a thorough inspection of all equipment involved, including the pulleys, ropes or cables, hooks, and attachments. Check for any signs of wear, damage, or deterioration. Ensure that all components are in good working condition and properly rated for the intended load.

2. Load Capacity:

Never exceed the maximum load capacity specified by the manufacturer for the wire pulleys and associated equipment. Determine the weight of the load accurately and select the appropriate pulley with the necessary load rating to ensure safe lifting operations.

3. Proper Installation:

Follow the manufacturer’s instructions for the correct installation of wire pulleys. Ensure that they are securely attached to stable anchor points or support structures capable of withstanding the load. Use appropriate fittings, connectors, and fasteners that are compatible with the pulley and the lifting system.

4. Rigging Techniques:

Use proper rigging techniques to attach the load to the wire pulley. Ensure that the load is properly balanced and securely attached to prevent shifting, slipping, or falling during lifting. Use appropriate slings, hooks, or other rigging hardware that are suitable for the load and compatible with the pulley.

5. Personal Protective Equipment (PPE):

Wear the necessary personal protective equipment, such as gloves, safety glasses, and hard hats, when operating wire pulleys for heavy lifting. PPE helps protect against potential hazards, such as hand injuries, impact hazards, or falling objects.

6. Communication:

Establish clear communication protocols between the operator and other personnel involved in the lifting operation. Use standardized hand signals or communication devices to ensure effective communication and coordination during the lifting process.

7. Clear Work Area:

Clear the work area of any obstacles, debris, or personnel who are not directly involved in the lifting operation. Ensure that there is sufficient space for the load to move vertically or horizontally without interference. Mark off the work area and restrict access to unauthorized personnel.

8. Operator Training:

Ensure that operators are properly trained and competent in using wire pulleys for heavy lifting. Training should cover equipment operation, safe lifting practices, load calculation, inspection procedures, and emergency protocols. Regularly update training to stay informed about the latest safety guidelines and best practices.

9. Regular Maintenance:

Schedule regular maintenance and inspections of wire pulleys and lifting equipment. Follow the manufacturer’s recommendations for lubrication, cleaning, and replacement of worn or damaged components. Promptly address any identified issues or concerns.

10. Emergency Preparedness:

Develop and communicate emergency procedures in case of accidents, equipment failure, or unexpected incidents during heavy lifting operations. Ensure that personnel are familiar with emergency shutdown procedures, evacuation routes, and the location of emergency equipment, such as fire extinguishers or first aid kits.

By adhering to these safety precautions, you can minimize the risks associated with using wire pulleys for heavy lifting and promote a safe working environment for all personnel involved.

In which industries and scenarios are wire pulleys commonly employed?

Wire pulleys find application in various industries and scenarios due to their versatility and efficiency. Here are some common industries and scenarios where wire pulleys are commonly employed:

1. Lifting and Rigging:

Wire pulleys are extensively used in lifting and rigging operations. They are employed in construction sites, manufacturing facilities, and transportation industries for tasks such as hoisting heavy equipment, moving materials, or rigging structures. Wire pulleys, in combination with wire ropes or cables, create mechanical advantage systems that allow heavy loads to be lifted with less effort.

2. Conveyor Systems:

Wire pulleys are essential components in conveyor systems. They are used to guide and support conveyor belts or wire mesh belts, ensuring the smooth movement and proper alignment of transported goods or materials. Wire pulleys help maintain tension in the conveyor belt, preventing slippage and ensuring efficient material handling in industries such as mining, agriculture, and logistics.

3. Automotive and Transportation:

Wire pulleys are utilized in various applications in the automotive and transportation sectors. They are commonly found in vehicle engines, where they play a role in driving auxiliary components such as alternators, water pumps, and power steering systems through serpentine belt arrangements. Wire pulleys are also used in bicycle derailleurs, enabling smooth shifting of gears by guiding the movement of the derailleur cable.

4. Window Treatments and Shades:

Wire pulleys are employed in window treatment systems, such as blinds, shades, and curtains. They enable the smooth operation of the cords or cables used to raise, lower, or adjust the window coverings. Wire pulleys ensure that the cords move freely and remain properly tensioned, allowing users to easily control the amount of light and privacy in a room.

5. Exercise Equipment:

Wire pulleys are commonly found in exercise machines and gym equipment. They are used to create resistance or tension in cable-based systems, enabling users to perform various exercises. Wire pulleys in exercise equipment contribute to the smooth and controlled movement of the cables, providing resistance for strength training or facilitating the range of motion for targeted muscle exercises.

6. Entertainment and Stage Systems:

Wire pulleys play a crucial role in entertainment and stage systems. They are utilized in theater rigging, concert productions, and other live performances to move scenery, lighting fixtures, and other equipment. Wire pulleys enable the precise and controlled movement of cables or ropes, allowing stage crews to perform scene changes, fly in props, or adjust lighting setups smoothly and safely.

7. DIY and Home Improvement:

Wire pulleys are often employed in various do-it-yourself (DIY) and home improvement projects. They can be used to create simple mechanical systems, such as garage door openers, homemade cranes, or manual lifting devices. Wire pulleys provide a cost-effective solution for redirecting or guiding wires or cables in DIY applications.

These are just a few examples of the industries and scenarios where wire pulleys are commonly employed. Wire pulleys offer versatility and efficiency, making them valuable tools in numerous applications.

editor by CX

2024-04-26