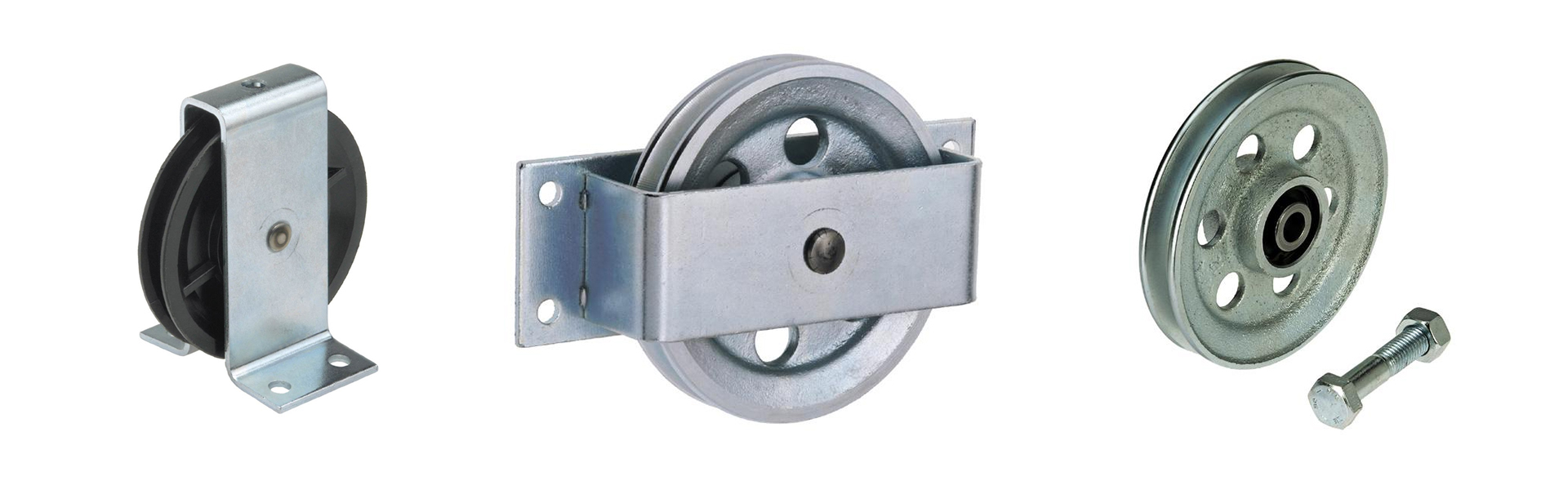

Product Description

Product Description

Product Description

| Item | Sheaves/Pulleys |

| Design | Can be at the customer’ request, tailor-made, at customer’s design |

| Application | Cranes, lifting hooks, lifting grabs, lifting beams |

| Material | SAE4140, SAE4150, SAE4160, 42CrMo, 42CrMo4,SAE1045,45#, stainless steel 410,stainless steel 304 |

| Standard | UIC 811-1, EN13261, GOST 31334, IRIS 16/95, KSR 9220, BS 5892, JIS E4502, TB/T 2945 |

| Size | From diameter 250mm to 1250mm. |

| Minimum order | 1 pc |

Manufacturing Process

1.Free forged or module forged

2.Rough machining process, to remove the surface forged oxidized black leather.

3.100% Ultrasonic Test ASTMA388

4.Heat Treatment according to request, Normalized, Quenched, Tempered….

5.Hardness test

6.Finishing Process to the dimensional state required by the drawing.

7.100% Magnetic Test ASTM E709 and 100% dimensional test

8.Painting or oil protecting TECTYL 506 or similar

9.Packing with boxes

Data Needed for Quotation

– Your own drawing

– Your requirement on material and necessary dimensional data

– Ask for recommend

Company Profile

ZheJiang CHINAMFG Machinery Co., Ltd., established in the year of 2012, is a professional supplier of material handling equipment, OEM machinery parts, various forging parts and casting parts.

Ebon’s products scope: cranes, hoists, magnets, grabs, hooks, wheels, drums, axles, lifting beams,bearing box, bearings, couplings,flanges etc. They are applied in wide range of field: Machinery, Mining, Hydro power Transportation, Construction…..

CHINAMFG has 5 reliable manufacturing factories to make sure stable supply and fast delivery for your business.

Our products are also exported to USA, Britain, Japan, South Korea, Russia, Indonesia, Thailand, India, Vietnam, Canada, Argentina, Paraguay etc more than 50 countries.

CHINAMFG team is loyal and committed to your success, and firmly believes that our products and services will increase the value and effectiveness of your business with following characters:

-Professional sales team, market promotion team and logistics team with more then 10 years experience .

-Loyal and Responsible Characters

-Efficient Work, Fast Response

-Responsible Quality Control Team

-Video the manufacturing process, the testing, and packing before delivery

1.Q: How about your delivery time?

A: Generally, it will take 7-30 days after receiving your advance payment. The specific delivery time depends on the items, transportation ways and the quantity of your order.

2.Q: Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

3.Q: Do you test all your goods before delivery?

A: Yes, we have 100% Ultrasonic test, Magnetic test or Liquid Penetration test before delivery

4.Q: How do you make our business long-term and good relationship?

A: (1) We keep good quality and competitive price to ensure our customers benefit ;

(2) We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

5.Q: I can’t see the goods or touch the goods, how can I deal with the risk involved?

A: Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Pressure Casting |

| Application: | Machinery Parts |

| Material: | Steel |

| Heat Treatment: | Quenching |

| Customization: |

Available

| Customized Request |

|---|

Are there any environmental considerations when using wire pulleys in outdoor applications?

Yes, there are several environmental considerations to keep in mind when using wire pulleys in outdoor applications. These considerations revolve around the impact on the environment and the sustainable use of resources. Here are some important environmental considerations:

1. Material Selection:

Choosing environmentally friendly materials for wire pulleys is crucial. Opting for materials that are recyclable, biodegradable, or made from renewable resources helps reduce the environmental impact. For example, pulleys made from recycled plastics or materials derived from sustainable sources can be more environmentally friendly compared to those made from virgin materials.

2. Chemical Exposure:

In outdoor applications, wire pulleys may be exposed to various environmental conditions, including exposure to chemicals such as acids, solvents, or corrosive substances. It is important to select pulleys that are resistant to such chemicals to prevent pollution or damage to the environment. Additionally, proper disposal of any chemicals used in pulley maintenance or cleaning is essential to minimize environmental harm.

3. Lubricants and Greases:

Wire pulleys often require lubrication to reduce friction and ensure smooth operation. When selecting lubricants or greases, it is important to choose environmentally friendly options that are biodegradable and have minimal impact on the ecosystem. Using eco-friendly lubricants helps to prevent contamination of soil or water sources in outdoor environments.

4. Wildlife Protection:

In outdoor applications, wire pulleys may be installed in areas inhabited by wildlife. It is essential to consider the potential impact on wildlife and take measures to minimize disturbances. This may include proper installation of pulleys to avoid disrupting animal habitats or using protective measures to prevent animals from getting entangled in the cables or pulleys.

5. Noise and Vibration:

Some outdoor applications may involve noise and vibration generated by wire pulleys. Excessive noise and vibration can have adverse effects on the environment, such as disturbing wildlife or nearby communities. Implementing noise reduction measures, such as using pulleys with noise-dampening features or proper insulation, helps mitigate the environmental impact.

6. End-of-Life Disposal:

Consider the end-of-life disposal of wire pulleys. Whenever possible, choose pulleys that can be recycled or have a minimal impact on the environment when they reach the end of their useful life. Proper recycling or disposal methods should be followed to reduce waste and prevent pollution.

7. Sustainable Manufacturing:

Consider selecting wire pulleys from manufacturers that prioritize sustainable practices in their manufacturing processes. Manufacturers that utilize renewable energy sources, reduce waste generation, and employ environmentally friendly production methods contribute to a more sustainable supply chain.

By considering these environmental considerations and making conscious choices, it is possible to minimize the environmental impact associated with using wire pulleys in outdoor applications. This ensures the sustainable use of resources and helps protect the surrounding ecosystem.

What safety precautions should be taken when using wire pulleys for heavy lifting?

When using wire pulleys for heavy lifting, it is crucial to follow specific safety precautions to prevent accidents, injuries, and damage. Here are some important safety measures to consider:

1. Equipment Inspection:

Prior to using wire pulleys, conduct a thorough inspection of all equipment involved, including the pulleys, ropes or cables, hooks, and attachments. Check for any signs of wear, damage, or deterioration. Ensure that all components are in good working condition and properly rated for the intended load.

2. Load Capacity:

Never exceed the maximum load capacity specified by the manufacturer for the wire pulleys and associated equipment. Determine the weight of the load accurately and select the appropriate pulley with the necessary load rating to ensure safe lifting operations.

3. Proper Installation:

Follow the manufacturer’s instructions for the correct installation of wire pulleys. Ensure that they are securely attached to stable anchor points or support structures capable of withstanding the load. Use appropriate fittings, connectors, and fasteners that are compatible with the pulley and the lifting system.

4. Rigging Techniques:

Use proper rigging techniques to attach the load to the wire pulley. Ensure that the load is properly balanced and securely attached to prevent shifting, slipping, or falling during lifting. Use appropriate slings, hooks, or other rigging hardware that are suitable for the load and compatible with the pulley.

5. Personal Protective Equipment (PPE):

Wear the necessary personal protective equipment, such as gloves, safety glasses, and hard hats, when operating wire pulleys for heavy lifting. PPE helps protect against potential hazards, such as hand injuries, impact hazards, or falling objects.

6. Communication:

Establish clear communication protocols between the operator and other personnel involved in the lifting operation. Use standardized hand signals or communication devices to ensure effective communication and coordination during the lifting process.

7. Clear Work Area:

Clear the work area of any obstacles, debris, or personnel who are not directly involved in the lifting operation. Ensure that there is sufficient space for the load to move vertically or horizontally without interference. Mark off the work area and restrict access to unauthorized personnel.

8. Operator Training:

Ensure that operators are properly trained and competent in using wire pulleys for heavy lifting. Training should cover equipment operation, safe lifting practices, load calculation, inspection procedures, and emergency protocols. Regularly update training to stay informed about the latest safety guidelines and best practices.

9. Regular Maintenance:

Schedule regular maintenance and inspections of wire pulleys and lifting equipment. Follow the manufacturer’s recommendations for lubrication, cleaning, and replacement of worn or damaged components. Promptly address any identified issues or concerns.

10. Emergency Preparedness:

Develop and communicate emergency procedures in case of accidents, equipment failure, or unexpected incidents during heavy lifting operations. Ensure that personnel are familiar with emergency shutdown procedures, evacuation routes, and the location of emergency equipment, such as fire extinguishers or first aid kits.

By adhering to these safety precautions, you can minimize the risks associated with using wire pulleys for heavy lifting and promote a safe working environment for all personnel involved.

Can you explain the fundamental principles of how wire pulleys work?

Wire pulleys operate based on a few fundamental principles that enable their functionality. Here’s an explanation of these principles:

1. Mechanical Advantage:

The primary principle behind wire pulleys is mechanical advantage. By using a pulley system, the force required to move a load can be reduced. When a wire or cable is looped around a pulley, the tension in the wire is distributed between the sections of wire on either side of the pulley. This distribution of tension allows the force applied to one side of the pulley to be multiplied on the other side, resulting in a mechanical advantage. The mechanical advantage depends on the number of pulleys in the system and the configuration of the pulleys, such as whether they are fixed or movable.

2. Friction Reduction:

Wire pulleys are designed to minimize friction between the wire or cable and the pulley itself. The pulley’s grooved wheel or sheave provides a smooth surface for the wire to pass over, reducing the resistance caused by friction. By minimizing friction, the pulley enables the wire to move more easily, requiring less force and effort to operate. Additionally, high-quality pulleys often incorporate bearings or bushings to further reduce friction and ensure smooth movement.

3. Directional Change:

Another principle of wire pulleys is directional change. A wire pulley allows the wire or cable to change its direction of movement. When the wire is pulled in one direction, it wraps around the pulley’s grooved wheel, changing its path. This change in direction is useful in various applications where the wire needs to be redirected or guided along a specific path. The pulley’s design ensures that the wire remains properly aligned and in contact with the grooved wheel, preventing it from slipping off during operation.

4. Load Distribution:

Wire pulleys also play a role in load distribution. When a load is suspended by a wire or cable passing over a pulley, the weight of the load is distributed between the sections of wire on either side of the pulley. This distribution of the load helps to balance the forces acting on the pulley system, reducing strain on the wire and ensuring stability during operation. Proper load distribution is crucial to prevent overloading the wire and pulley system, which could lead to failure or damage.

5. Tension Management:

Tension management is an important principle in wire pulley systems. The pulley helps manage and distribute tension along the wire or cable. By adjusting the configuration of the pulleys, tension can be controlled and balanced throughout the system. Proper tension management is essential for maintaining the stability and efficiency of the pulley system, preventing slack or excessive tension that may affect performance or safety.

By leveraging these fundamental principles, wire pulleys enable the smooth movement, force multiplication, directional change, load distribution, and tension management of wires or cables in various applications.

editor by CX

2024-05-03