Product Description

Product Description

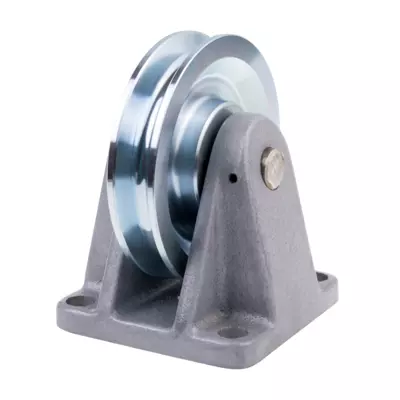

V-pulley,

European Standard: V-belt pulley for taper bushes: SPZ, SPA, SPB, SPC, up to 10 grooves

American standard 3V

Why Choose Us?

1. HangZhou Vision Chain Transmisison Co Ltd. Is UK- Investment Chain manufacture in HangZhou, China. Found in 2004. We have 1 Chain manufacturer and 1 Sprocket manufacturer.

2. Qualified Alloy steel chain put our TV brand chain in the top quality level in China. We are honoured with ISO9001. ISO14001. AAA Credit certificate.

3. We have been producing all kinds of standard chains and special chain: Driving Chain, Agriculture Chain, Conveyor Chain, Long Pitch Conveyor Chain, Stainless Steel Chain, Hoisting Chain, Motorcycle Chain, Dropped Forged Rivetless Chain and so on.

V-Pulley:

1. BS3790-1981

2. SPZ-1-10 / SPA-1-10 /SPB-1-10/ SPC-1-10

3. Taper Bore V-Pulley

4. Stock Bore V-Pulley

5. Adjustable Speed V-Pulley

Product Attribute

|

Certification |

ISO |

|

Pulley Sizes |

Type C |

|

Manufacturing Process |

Casting |

|

Material |

Cast Iron |

|

Surface Treatment |

Oxygenation |

|

Application |

Chemical Industry, Mining Transport |

|

Pulley |

Belt Transmission |

|

Manufacturing Method |

Cast |

|

Toothed Portion Shape |

Belt Transmission |

|

Type |

Circular Pulley |

| port |

ZheJiang |

| payment |

L/C, T/T, D/P, Western Union, Paypal |

| Package |

Box and Woodencase |

Detailed Photos

Product Parameters

Certifications

Our Advantages

Packaging & Shipping

WHY CHOOSE US

Comprehensive Product Portfolio We produce and supply a wide range of power transmission

products including drive chains, leaf chains, conveyor chains, agricultural chains, sprockets, and

couplings. This one-store-for-all shopping experience will significantly reduce your searching costs while

guarantee youfind what you want at 1 click.

Value Choice Products Our products are the best combination of quality and price, and you get what

you want within your budgets

Seasoned Sales Associates and Engineers We have 15 seasoned sales associates and 5 engineers;

on our team at your disposal any time when you need a helping hand. They are well trained with industry

know-now and will always respond to your requests within 24 hours.

100% Customer Retention Rate Our regular customers from overseas come back not just for our

premium quality products, but for the superior services that we’ve provided over the years

FAQ

Q1: What’s your average lead time?

A: It varies. Our regular end-to-end lead time is 1-2 months.. We also provide express shipments for rush orders. For details,please consult our sales associate.

Q2: Is your price better than your competitors given the same quality?

A: Definitely YES. We provide the most competitive price in the power transmission industry. If price disparity exists, we’ll be more than happy to do a price match.

Q3: Can you make chains according to my CAD drawings?

A: Yes. Besides the regular standard chains, we produce non-standard and custom-design products to meet the specific technical requirements. In reality, a sizable portion of our production capacity is assigned to make non-standard products.

Q4: Can we inspect the goods before shipment?

A: Yes. You or your representative or any third-party inspection party assigned is allowed access to our facility and do the inspection.

Q5: What kind of payment method is acceptable for your mill?

A: We’re flexible. We take T/T, L/C, or any other online payment methods so long as it’s applicable for you.

Q6: What if I have any other questions?

A: Whenever in doubt, you’re always encouraged to consult our sales associate any time – They will help you to your satisfaction.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Products Name: | Wire Mesh Conveyor Belt |

|---|---|

| Wire Diameter: | 0.5-2.5mm |

| Width: | 0.3-1.5m |

| Length: | 1m-50m |

| Surface: | Galvanized, PVC Coated |

| Price: | Competitive Price |

| Customization: |

Available

| Customized Request |

|---|

What is the role of wire pulleys in maintaining proper tension in cable-based systems?

Wire pulleys play a crucial role in maintaining proper tension in cable-based systems. They help distribute and manage the tension in the cables, ensuring smooth and efficient operation. Here’s a detailed explanation of the role of wire pulleys in maintaining proper tension:

1. Load Distribution:

Wire pulleys help distribute the load evenly across the cables in a system. As the cables pass over the pulleys, they change direction, which spreads the tension along the length of the cables. This prevents excessive stress and strain on any specific section of the cables, promoting uniform tension distribution.

2. Directional Change:

Wire pulleys facilitate changes in the direction of the cables. By redirecting the cables, pulleys allow for efficient routing and alignment, ensuring that the cables follow the desired path. This is particularly important in complex cable-based systems where cables need to navigate around obstacles or change directions at different points.

3. Tension Adjustment:

Wire pulleys enable tension adjustment in cable-based systems. By altering the position of the pulleys or changing the number of pulleys in the system, the tension in the cables can be adjusted as needed. This flexibility allows for fine-tuning the tension to achieve optimal performance and stability in the system.

4. Cable Retention:

Wire pulleys help retain the cables in their proper position. The grooved or contoured surface of the pulleys prevents the cables from slipping or coming off their intended path. This is particularly important in applications where maintaining cable alignment and position is critical for the system’s functionality and safety.

5. Friction Reduction:

Well-designed wire pulleys minimize friction between the cables and the pulley surfaces. Reduced friction helps to prevent excessive wear on the cables and reduces the energy required to move the cables. This results in smoother operation, lower power consumption, and less strain on the entire cable-based system.

6. Cable Protection:

Wire pulleys provide protection to the cables from external elements. The pulley’s smooth and rounded surfaces prevent sharp bends or kinks in the cables, reducing the risk of cable damage or fatigue. Additionally, pulleys can be designed with coatings or materials that offer resistance to corrosion, abrasion, or chemical exposure, further safeguarding the cables.

7. System Stability:

By maintaining proper tension in the cables, wire pulleys contribute to the overall stability of the cable-based system. Balanced tension prevents slack or excessive stretching of the cables, ensuring that they maintain the desired position and alignment. This stability is crucial for the system’s performance, reliability, and safety.

It is important to select wire pulleys that are appropriately sized, rated for the intended load, and compatible with the cable diameter and construction. Regular maintenance and inspection of the pulleys are also necessary to ensure they remain in good working condition and continue to perform their role effectively.

By utilizing properly designed and installed wire pulleys, cable-based systems can maintain optimal tension, promoting efficient operation, longevity of cables, and overall system reliability.

What are some real-world examples of wire pulleys in construction and manufacturing?

Wire pulleys are widely used in construction and manufacturing industries to facilitate various tasks related to lifting, moving, and material handling. Here are some real-world examples of how wire pulleys are utilized in these industries:

Construction:

1. Crane Systems: Wire pulleys are an integral part of crane systems used in construction. They enable the lifting and movement of heavy materials and equipment on construction sites. Wire pulleys are commonly employed in tower cranes, mobile cranes, and crawler cranes to provide mechanical advantage and precise control over the loads.

2. Scaffolding Systems: In construction projects, wire pulleys are often incorporated into scaffolding systems. They assist in lifting construction materials, tools, and equipment to different levels, making it easier for workers to access the required items during building construction or maintenance.

3. Conveyor Systems: Wire pulleys are utilized in conveyor systems within construction sites. They help transport materials, such as aggregates, concrete blocks, or bricks, along the conveyor belts, optimizing the material handling process and increasing construction efficiency.

Manufacturing:

1. Assembly Lines: Wire pulleys play a crucial role in manufacturing assembly lines. They are used to lift and move components during the assembly process, ensuring smooth and efficient production. Wire pulleys integrated into automated systems provide precise control over the movement of parts, leading to increased productivity and accuracy.

2. Material Handling Equipment: Wire pulleys are utilized in various material handling equipment, such as forklifts and cranes, used in manufacturing facilities. They are employed to lift, lower, and position heavy loads, contributing to the efficient movement of materials within the production environment.

3. Conveyor Systems: Similar to the construction industry, wire pulleys are employed in conveyor systems within manufacturing facilities. They facilitate the movement of products, components, or raw materials along the conveyor belts, ensuring a continuous flow of materials during the manufacturing process.

4. Robotics and Automation: Wire pulleys are integrated into robotic systems and automated machinery in manufacturing. They enable the precise and controlled movement of robotic arms or end-effectors, allowing for efficient and accurate handling of materials or components in assembly, packaging, or machining processes.

These are just a few examples of how wire pulleys are utilized in construction and manufacturing. Their versatile nature and ability to provide mechanical advantage and precise control make them indispensable in these industries, contributing to improved efficiency and productivity in material handling operations.

In which industries and scenarios are wire pulleys commonly employed?

Wire pulleys find application in various industries and scenarios due to their versatility and efficiency. Here are some common industries and scenarios where wire pulleys are commonly employed:

1. Lifting and Rigging:

Wire pulleys are extensively used in lifting and rigging operations. They are employed in construction sites, manufacturing facilities, and transportation industries for tasks such as hoisting heavy equipment, moving materials, or rigging structures. Wire pulleys, in combination with wire ropes or cables, create mechanical advantage systems that allow heavy loads to be lifted with less effort.

2. Conveyor Systems:

Wire pulleys are essential components in conveyor systems. They are used to guide and support conveyor belts or wire mesh belts, ensuring the smooth movement and proper alignment of transported goods or materials. Wire pulleys help maintain tension in the conveyor belt, preventing slippage and ensuring efficient material handling in industries such as mining, agriculture, and logistics.

3. Automotive and Transportation:

Wire pulleys are utilized in various applications in the automotive and transportation sectors. They are commonly found in vehicle engines, where they play a role in driving auxiliary components such as alternators, water pumps, and power steering systems through serpentine belt arrangements. Wire pulleys are also used in bicycle derailleurs, enabling smooth shifting of gears by guiding the movement of the derailleur cable.

4. Window Treatments and Shades:

Wire pulleys are employed in window treatment systems, such as blinds, shades, and curtains. They enable the smooth operation of the cords or cables used to raise, lower, or adjust the window coverings. Wire pulleys ensure that the cords move freely and remain properly tensioned, allowing users to easily control the amount of light and privacy in a room.

5. Exercise Equipment:

Wire pulleys are commonly found in exercise machines and gym equipment. They are used to create resistance or tension in cable-based systems, enabling users to perform various exercises. Wire pulleys in exercise equipment contribute to the smooth and controlled movement of the cables, providing resistance for strength training or facilitating the range of motion for targeted muscle exercises.

6. Entertainment and Stage Systems:

Wire pulleys play a crucial role in entertainment and stage systems. They are utilized in theater rigging, concert productions, and other live performances to move scenery, lighting fixtures, and other equipment. Wire pulleys enable the precise and controlled movement of cables or ropes, allowing stage crews to perform scene changes, fly in props, or adjust lighting setups smoothly and safely.

7. DIY and Home Improvement:

Wire pulleys are often employed in various do-it-yourself (DIY) and home improvement projects. They can be used to create simple mechanical systems, such as garage door openers, homemade cranes, or manual lifting devices. Wire pulleys provide a cost-effective solution for redirecting or guiding wires or cables in DIY applications.

These are just a few examples of the industries and scenarios where wire pulleys are commonly employed. Wire pulleys offer versatility and efficiency, making them valuable tools in numerous applications.

editor by CX

2024-04-24