Product Description

Product Description

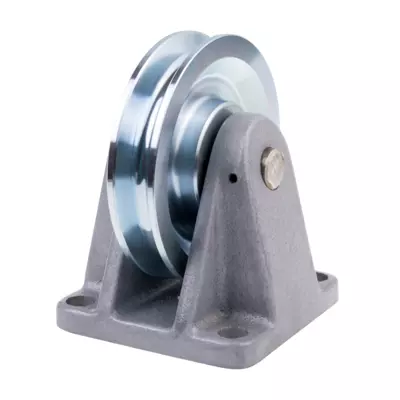

Traverse bobbin winding machine wire traverse roller guide pulley

Manufacturer of automatic linear transmission gear with well-equipped testing facilities and strong technical force

SIZE: GP15 GP20 GP30 GP40 GP50 GP60

| Size | Pass Steel Wire Diameter (mm) |

| GP15 | 1mm |

| GP20 | 1-1.5mm |

| GP30 | 1.5-3mm |

| GP40 | 6mm |

| GP50 GP60 | 6-8mm |

The Following is Customized Product

Adjustable Wire Wheel (1-14mm Wire), Price: $25-$28 USD

Usage in Traverse Unit

Packaging & Shipping

|

Package Material

|

Wooden Box or Carton |

|

Package Detail

|

1piece or 5 pieces per carton package or wooden carton |

|

Delivery Way

|

Deliver the goods by express, like UPS, DHL, FedEx or by sea shipment or according to customer’s requirement |

Product Application

Rolling ring drive/ traverse unit device is mostly used in industry. Used in textile machine, wire spooling machine, traverse winding machine, wire winding machine, linear drive system, medical equipment, etc.

Different Type of Product

Other Rolling Ring Drive Spare Parts

(Please contact us if you need the following spare parts)

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in carton boxes or wooden boxes.

Q2. What is your terms of payment?

A: T/T 100% paymeny in advance, or 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will send this product within 3 or 5 days after receiving your payment. The specific delivery time depends on the items and the quantity of your order.

Q5. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Color: | Fixed |

|---|---|

| Customized: | Customized |

| Standard: | National |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the quality and precision of wire pulleys affect their performance?

The quality and precision of wire pulleys have a significant impact on their performance in lifting and pulling tasks. Here’s how the quality and precision of wire pulleys affect their performance:

1. Load Capacity:

High-quality wire pulleys are designed and manufactured to withstand specified load capacities. They undergo rigorous testing to ensure they can handle the intended loads safely. A pulley with accurate load capacity information allows operators to select the appropriate pulley for their specific lifting or pulling task, preventing overloading and potential equipment failure.

2. Durability:

Quality wire pulleys are constructed using robust materials and precise manufacturing processes. This enhances their durability, allowing them to withstand repeated use, heavy loads, and harsh operating conditions. A durable pulley resists wear, corrosion, and deformation, ensuring reliable performance and extending its service life.

3. Efficiency:

Precision engineering and manufacturing of wire pulleys contribute to their efficiency during lifting and pulling operations. High-quality pulleys are designed to minimize friction, which reduces energy loss and facilitates smoother movement of the load. This improves the overall efficiency of the lifting system, requiring less force or power input to achieve the desired results.

4. Smooth Operation:

Quality wire pulleys are manufactured with precise dimensions and tolerances. This results in smooth operation and reduced friction between the pulley and the rope or cable. Smooth operation minimizes wear on the rope or cable, reduces the risk of snags or jams, and ensures consistent and predictable movement of the load.

5. Safety:

High-quality wire pulleys undergo stringent quality control measures to ensure they meet safety standards and regulations. They are designed with features such as accurate load ratings, safety factor considerations, and appropriate certifications. A pulley with reliable safety features reduces the risk of accidents, equipment failure, and injuries during lifting or pulling operations.

6. Noise and Vibration:

Precision manufacturing of wire pulleys helps to minimize noise and vibration during operation. Well-balanced pulleys with accurate alignment and smooth rotation produce less noise and vibration, creating a quieter and more comfortable working environment for operators.

7. Compatibility:

Quality wire pulleys are designed to be compatible with various lifting systems, ropes, or cables. Precise dimensions and standardized interfaces ensure that the pulleys can be easily integrated into existing equipment or rigging setups. This provides flexibility and convenience when selecting and using wire pulleys in different applications.

When choosing wire pulleys, it is important to consider the reputation and reliability of the manufacturer or supplier. Trusted manufacturers with a track record of producing high-quality pulleys are more likely to deliver products that meet or exceed performance expectations.

By prioritizing quality and precision in wire pulleys, you can expect improved performance, increased safety, enhanced durability, and optimal efficiency in your lifting and pulling operations.

Can wire pulleys be used in both stationary and mobile applications?

Yes, wire pulleys can be used in both stationary and mobile applications. They are versatile mechanical devices that can facilitate various lifting and moving tasks in different environments. Here’s how wire pulleys can be utilized in both stationary and mobile applications:

Stationary Applications:

In stationary applications, wire pulleys are often used in fixed locations where the pulley system remains in place. Some examples of stationary applications include:

– Construction sites: Wire pulleys are commonly used in construction projects for lifting heavy materials to different levels or moving them horizontally. They can be installed on cranes, scaffolding systems, or fixed structures to facilitate the movement of construction materials.

– Manufacturing facilities: Wire pulleys are employed in manufacturing plants for various tasks, such as lifting components during assembly processes or moving materials along conveyor systems. They can be integrated into production lines or workstations to enhance efficiency and streamline operations.

– Warehouses and distribution centers: Wire pulleys are utilized in warehouses and distribution centers for lifting and moving pallets, crates, or other heavy loads. They can be incorporated into overhead crane systems or used in conjunction with forklifts to optimize the handling of goods.

Mobile Applications:

In mobile applications, wire pulleys are designed to be portable and adaptable, allowing them to be easily transported and deployed in different locations. Some examples of mobile applications include:

– Rigging and hoisting: Wire pulleys are used in rigging and hoisting operations that require mobility. They can be employed in scenarios such as lifting equipment or materials onto elevated platforms, performing maintenance tasks on structures, or setting up temporary installations.

– Rescue and recovery operations: Wire pulleys are utilized in emergency situations, such as rescue and recovery operations. They can be utilized to create mechanical advantage systems for lifting or lowering individuals or objects in confined spaces, steep terrains, or other challenging environments.

– Outdoor activities and sports: Wire pulleys find applications in outdoor activities and sports that involve zip lines, rock climbing, or aerial maneuvers. They are used to create controlled movement along a cable or rope, providing participants with thrilling experiences while ensuring safety and stability.

Whether in stationary or mobile applications, wire pulleys offer advantages such as mechanical advantage, load distribution, and precise control. Their versatility makes them suitable for a wide range of tasks, and their adaptability allows them to be used in various settings and environments.

Are there different sizes and configurations of wire pulleys available for different tasks?

Yes, there are various sizes and configurations of wire pulleys available to suit different tasks and applications. The selection of the appropriate wire pulley depends on factors such as the intended use, load capacity, space constraints, and environmental conditions. Here are some examples of the different sizes and configurations of wire pulleys:

1. Diameter:

Wire pulleys come in different diameters to accommodate different rope or cable sizes. Smaller diameter pulleys are typically used with thinner ropes or cables, while larger diameter pulleys are suitable for thicker ropes or cables. The diameter of the pulley affects the bending radius of the rope and can impact the efficiency and lifespan of the pulley system.

2. Number of Sheaves:

Wire pulleys can have a single sheave or multiple sheaves. Single sheave pulleys are commonly used for simple lifting or guiding tasks. Multiple sheave pulleys, also known as block and tackle systems, consist of two or more sheaves mounted on a common frame. They provide increased mechanical advantage by distributing the load among the multiple sheaves.

3. Fixed or Swivel:

Wire pulleys can be either fixed or swivel. Fixed pulleys have a stationary axle and only change the direction of the force applied. Swivel pulleys, on the other hand, have a rotating axle, allowing for both the change of direction and the rotation of the load. Swivel pulleys are commonly used in applications where the load needs to be maneuvered or guided in different directions.

4. Bearing Type:

Wire pulleys can have different types of bearings to reduce friction and improve efficiency. Common bearing types used in wire pulleys include ball bearings and roller bearings. Ball bearings offer low friction and smooth rotation, while roller bearings are suitable for handling heavier loads. The choice of bearing type depends on the load capacity and desired performance of the pulley system.

5. Material:

Wire pulleys are available in various materials to suit different environments and applications. Common materials used for wire pulleys include steel, stainless steel, aluminum, and nylon. Steel and stainless steel pulleys are known for their strength and durability, making them suitable for heavy-duty applications. Aluminum pulleys are lightweight and corrosion-resistant, often used in applications where weight reduction is important. Nylon pulleys offer low friction and quiet operation, making them suitable for applications that require smooth and noiseless movement.

6. Specialty Configurations:

There are also specialty configurations of wire pulleys designed for specific tasks or industries. For example, snatch blocks feature a hinged design that allows them to be opened and closed around a rope or cable, making them suitable for rigging applications. High-speed pulleys are designed to handle fast rope or cable movement, commonly used in applications such as zip lines or stage rigging.

These are just a few examples of the different sizes and configurations of wire pulleys available. It’s important to choose the right size and configuration of wire pulley that matches the specific requirements of the task or application to ensure optimal performance, efficiency, and safety.

editor by CX

2024-05-07