Product Description

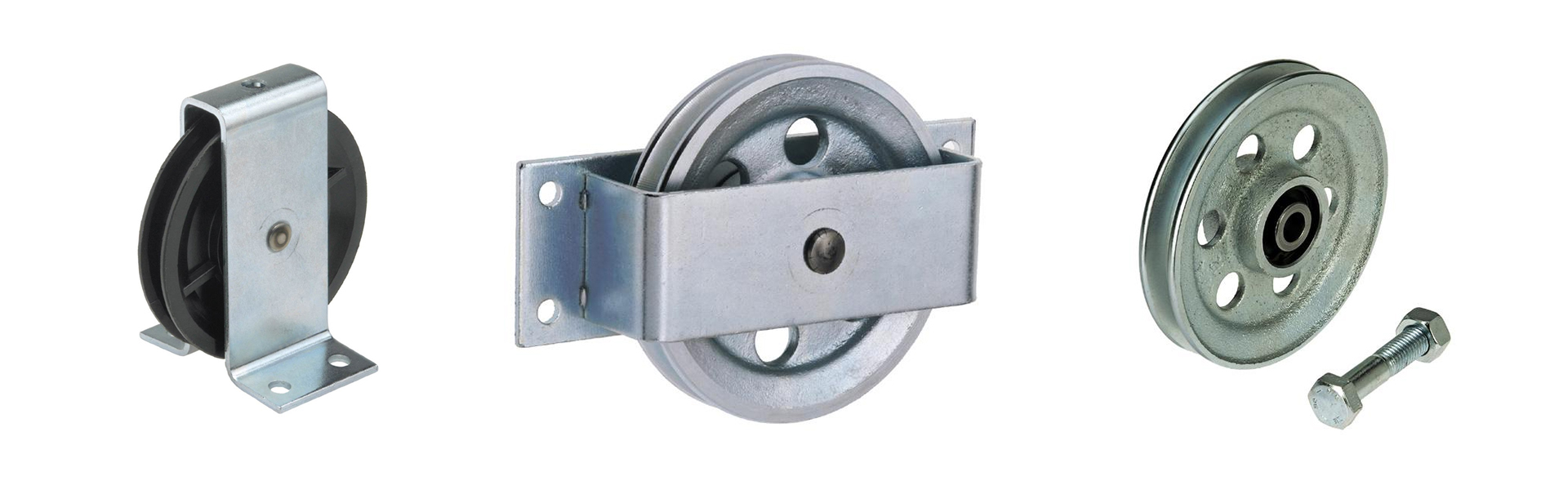

SBD Closed Type Wire Rope Pulley Block Single Sheave with Hook

- Closed Type Pulley Block

- 3211 Pulley Block

- Cable Pulley

- Lifting Block

- Product description: 3211 Closed Type Wire Rope Pulley Block Single Sheave with Hook is 1 kind of low-end block for Wire Rope, it has simple structure, but the size and working load limit is same as Open Type Pulley Bl

| PULLEY SNATCH BLOCK SINGLE SHEAVE WITH HOOK | ||||

| SIZE | CODE | S.W.L | DIAM OF ROPE | N.W |

| (IN) | (TON) | (MM) | (KG) | |

| 2 | SBD02 | 0.25 | 6 | 0.55 |

| 3 | SBD03 | 0.5 | 8 | 1.15 |

| 4 | SBD04 | 1 | 10 | 2 |

| 5 | SBD05 | 1.5 | 13 | 3.2 |

| 6 | SBD06 | 2 | 16 | 4.8 |

| 7 | SBD07 | 3 | 19 | 7.8 |

| 8 | SBD08 | 4 | 22 | 10 |

| 10 | SBD10 | 5 | 25 | 14 |

| 12 | SBD12 | 6 | 28 | 18 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Type: | Hook |

| Material: | Alloy |

| Number of sheaves: | 1 |

| Control: | Manual |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do advancements in materials and design impact the development of modern wire pulleys?

Advancements in materials and design have a significant impact on the development of modern wire pulleys. These advancements drive innovation, improve performance, and expand the range of applications for wire pulleys. Here’s a detailed explanation of how advancements in materials and design influence the development of modern wire pulleys:

1. Material Selection:

New materials with enhanced properties are continuously being developed, offering improved strength, durability, and resistance to wear. Advancements in materials science have led to the availability of lightweight yet high-strength materials, such as carbon fiber composites or advanced polymers. These materials allow for the design of wire pulleys that are stronger, lighter, and more efficient.

2. Friction Reduction:

Advancements in materials and surface treatments have led to the development of low-friction pulley coatings and materials. These innovations minimize friction between the cables and pulley surfaces, resulting in smoother operation, reduced energy loss, and increased efficiency. Low-friction materials, such as self-lubricating polymers or ceramic coatings, are now commonly used in modern wire pulleys.

3. Design Optimization:

Advancements in design tools and techniques, such as computer-aided design (CAD) and finite element analysis (FEA), have revolutionized the design process for wire pulleys. Designers can now simulate and optimize the performance of pulleys under different loads and operating conditions. This allows for the creation of pulleys with optimized shapes, sizes, and configurations, resulting in improved functionality and efficiency.

4. Load Capacity and Safety:

Advancements in materials and design have enabled the development of wire pulleys with higher load capacities and improved safety features. Pulleys can now be engineered to withstand heavier loads, ensuring reliable operation in demanding applications. Additionally, safety features such as built-in braking systems or load-limiting mechanisms can be incorporated into pulley designs to prevent overloading and enhance operator safety.

5. Specialized Applications:

New materials and design advancements have expanded the range of specialized applications for wire pulleys. For example, in high-temperature environments, pulleys made from heat-resistant materials can be used. In corrosive or abrasive environments, pulleys with specialized coatings or materials that offer superior resistance to corrosion or wear can be employed. These advancements allow for the customization of pulleys to meet specific application requirements.

6. Noise and Vibration Reduction:

Advancements in design and materials have also addressed the issue of noise and vibration generated by wire pulleys. Innovations such as noise-dampening features, vibration-absorbing materials, or improved bearing technologies help minimize noise and vibration levels, enhancing user comfort and reducing the environmental impact.

7. Environmental Considerations:

Advancements in materials have led to the availability of environmentally friendly options for wire pulleys. Sustainable materials, such as recycled plastics or bio-based composites, can be used to reduce the environmental footprint of pulley manufacturing. Additionally, design improvements can optimize the energy efficiency of pulleys, contributing to a more sustainable and eco-friendly operation.

Overall, advancements in materials and design have transformed the development of modern wire pulleys. These advancements have resulted in pulleys that are stronger, lighter, more efficient, and better suited to meet the evolving needs of various industries and applications.

What safety precautions should be taken when using wire pulleys for heavy lifting?

When using wire pulleys for heavy lifting, it is crucial to follow specific safety precautions to prevent accidents, injuries, and damage. Here are some important safety measures to consider:

1. Equipment Inspection:

Prior to using wire pulleys, conduct a thorough inspection of all equipment involved, including the pulleys, ropes or cables, hooks, and attachments. Check for any signs of wear, damage, or deterioration. Ensure that all components are in good working condition and properly rated for the intended load.

2. Load Capacity:

Never exceed the maximum load capacity specified by the manufacturer for the wire pulleys and associated equipment. Determine the weight of the load accurately and select the appropriate pulley with the necessary load rating to ensure safe lifting operations.

3. Proper Installation:

Follow the manufacturer’s instructions for the correct installation of wire pulleys. Ensure that they are securely attached to stable anchor points or support structures capable of withstanding the load. Use appropriate fittings, connectors, and fasteners that are compatible with the pulley and the lifting system.

4. Rigging Techniques:

Use proper rigging techniques to attach the load to the wire pulley. Ensure that the load is properly balanced and securely attached to prevent shifting, slipping, or falling during lifting. Use appropriate slings, hooks, or other rigging hardware that are suitable for the load and compatible with the pulley.

5. Personal Protective Equipment (PPE):

Wear the necessary personal protective equipment, such as gloves, safety glasses, and hard hats, when operating wire pulleys for heavy lifting. PPE helps protect against potential hazards, such as hand injuries, impact hazards, or falling objects.

6. Communication:

Establish clear communication protocols between the operator and other personnel involved in the lifting operation. Use standardized hand signals or communication devices to ensure effective communication and coordination during the lifting process.

7. Clear Work Area:

Clear the work area of any obstacles, debris, or personnel who are not directly involved in the lifting operation. Ensure that there is sufficient space for the load to move vertically or horizontally without interference. Mark off the work area and restrict access to unauthorized personnel.

8. Operator Training:

Ensure that operators are properly trained and competent in using wire pulleys for heavy lifting. Training should cover equipment operation, safe lifting practices, load calculation, inspection procedures, and emergency protocols. Regularly update training to stay informed about the latest safety guidelines and best practices.

9. Regular Maintenance:

Schedule regular maintenance and inspections of wire pulleys and lifting equipment. Follow the manufacturer’s recommendations for lubrication, cleaning, and replacement of worn or damaged components. Promptly address any identified issues or concerns.

10. Emergency Preparedness:

Develop and communicate emergency procedures in case of accidents, equipment failure, or unexpected incidents during heavy lifting operations. Ensure that personnel are familiar with emergency shutdown procedures, evacuation routes, and the location of emergency equipment, such as fire extinguishers or first aid kits.

By adhering to these safety precautions, you can minimize the risks associated with using wire pulleys for heavy lifting and promote a safe working environment for all personnel involved.

How do wire pulleys help in the lifting and moving of heavy loads?

Wire pulleys play a crucial role in lifting and moving heavy loads by utilizing the principles of mechanical advantage. They enable the application of less force to lift or move a heavy object by distributing the load over multiple ropes or cables. Here’s how wire pulleys help in the lifting and moving of heavy loads:

1. Multiplying Force:

Wire pulleys create a mechanical advantage by changing the direction of the force applied. When a rope or cable is threaded through a pulley system, the force required to lift the load is distributed between the sections of the rope connected to the pulley. By using multiple pulleys, the force can be further divided, resulting in a significant reduction in the force required to lift the load. This multiplication of force allows heavy loads to be lifted with less effort.

2. Changing Direction:

Wire pulleys also allow the force applied to be redirected, enabling lifting or moving in different directions. By changing the direction of the force, the operator can use a more convenient or advantageous angle for lifting the load. Wire pulleys provide flexibility in maneuvering heavy objects, especially when space or accessibility is limited.

3. Increasing Distance:

Another way wire pulleys assist in lifting heavy loads is by increasing the distance over which the force is applied. The length of the rope or cable used with the pulley system can be extended, allowing the operator to exert force over a larger distance. This increased distance results in a mechanical advantage, reducing the force required to lift the load.

4. Load Distribution:

Wire pulleys aid in load distribution, especially when multiple pulleys are used in combination. The weight of the load is distributed evenly across the ropes or cables connected to the pulleys. This balanced distribution minimizes stress on individual ropes or cables, ensuring that the load is lifted or moved safely and efficiently.

5. Control and Precision:

Wire pulleys provide control and precision in lifting and moving operations. The operator can adjust the tension in the ropes or cables by manipulating the pulleys, allowing for smooth and controlled lifting or movement of heavy objects. This level of control is crucial for tasks that require precise positioning or delicate handling of the load.

By employing wire pulleys in lifting and moving operations, the mechanical advantage gained significantly reduces the force required, making it easier and more efficient to handle heavy loads. Wire pulleys enable operators to overcome the limitations of their physical strength and perform tasks that would otherwise be impractical or impossible without the use of mechanical assistance.

editor by CX

2024-05-08