Product Description

Product Description

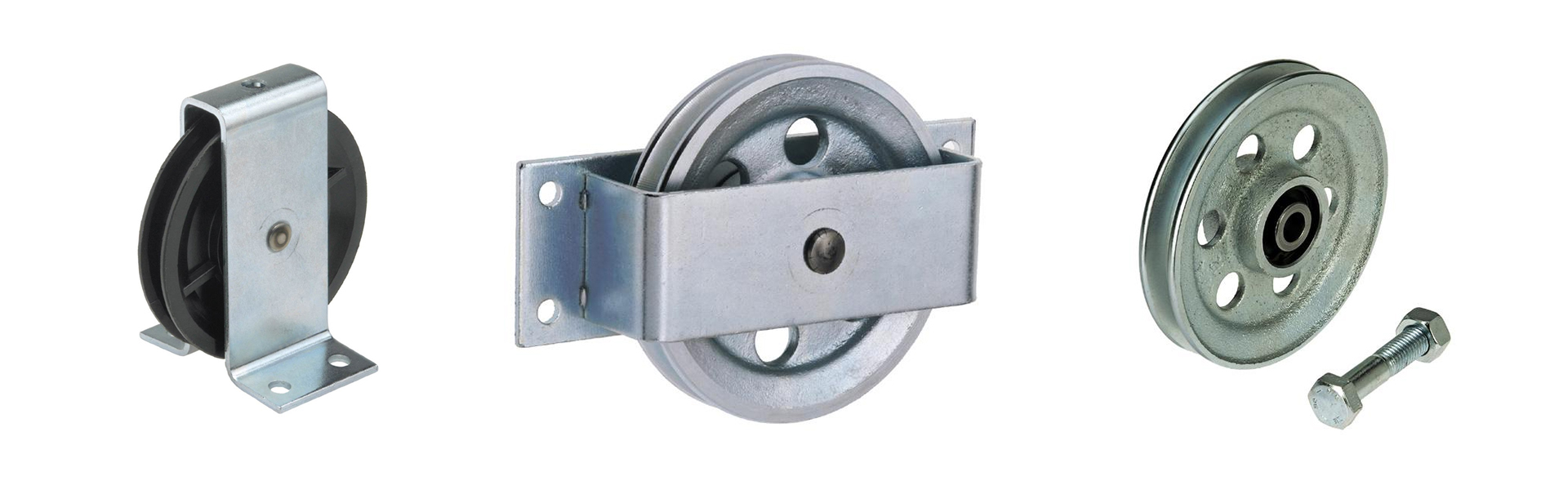

A wire rope sheave, also known as a pulley or a block, is a wheel with a groove around its circumference used for guiding a wire rope or cable. These sheaves are typically made of metal and can vary in size depending on the application. The groove in the sheave prevents the wire rope from slipping off and provides support as the rope moves.

Applications

Cranes and Hoists: In crane and hoist systems, wire rope sheaves are used to guide and support the lifting cables. They help in smoothly lifting and lowering heavy loads.

Elevators: Elevators use wire rope sheaves to move the elevator car up and down along the shaft. These sheaves are integral components of elevator systems, ensuring safe and efficient vertical transportation.

Mining: Wire rope sheaves are employed in mining operations for tasks such as hauling materials and equipment. They are crucial for maintaining the integrity of the wire ropes used in mining applications.

Marine and Shipping: On ships and boats, wire rope sheaves are used in various rigging applications, such as lifting cargo, anchoring, and mooring. They help in the efficient handling of heavy loads on board.

Construction: Construction sites utilize wire rope sheaves in equipment like cranes, winches, and hoists for lifting construction materials, machinery, and personnel to different heights.

Material Handling: Wire rope sheaves are also utilized in material handling equipment such as conveyor systems and lifting mechanisms in warehouses, factories, and distribution centers.

Agriculture: Agricultural machinery often employs wire rope sheaves for tasks like lifting heavy agricultural equipment, operating irrigation systems, and handling bales of hay or other materials.

Machinery processing

Our equipments

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Shape: | Round |

|---|---|

| Certification: | ISO 9001 |

| Sling Color: | Custom |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there any environmental considerations when using wire pulleys in outdoor applications?

Yes, there are several environmental considerations to keep in mind when using wire pulleys in outdoor applications. These considerations revolve around the impact on the environment and the sustainable use of resources. Here are some important environmental considerations:

1. Material Selection:

Choosing environmentally friendly materials for wire pulleys is crucial. Opting for materials that are recyclable, biodegradable, or made from renewable resources helps reduce the environmental impact. For example, pulleys made from recycled plastics or materials derived from sustainable sources can be more environmentally friendly compared to those made from virgin materials.

2. Chemical Exposure:

In outdoor applications, wire pulleys may be exposed to various environmental conditions, including exposure to chemicals such as acids, solvents, or corrosive substances. It is important to select pulleys that are resistant to such chemicals to prevent pollution or damage to the environment. Additionally, proper disposal of any chemicals used in pulley maintenance or cleaning is essential to minimize environmental harm.

3. Lubricants and Greases:

Wire pulleys often require lubrication to reduce friction and ensure smooth operation. When selecting lubricants or greases, it is important to choose environmentally friendly options that are biodegradable and have minimal impact on the ecosystem. Using eco-friendly lubricants helps to prevent contamination of soil or water sources in outdoor environments.

4. Wildlife Protection:

In outdoor applications, wire pulleys may be installed in areas inhabited by wildlife. It is essential to consider the potential impact on wildlife and take measures to minimize disturbances. This may include proper installation of pulleys to avoid disrupting animal habitats or using protective measures to prevent animals from getting entangled in the cables or pulleys.

5. Noise and Vibration:

Some outdoor applications may involve noise and vibration generated by wire pulleys. Excessive noise and vibration can have adverse effects on the environment, such as disturbing wildlife or nearby communities. Implementing noise reduction measures, such as using pulleys with noise-dampening features or proper insulation, helps mitigate the environmental impact.

6. End-of-Life Disposal:

Consider the end-of-life disposal of wire pulleys. Whenever possible, choose pulleys that can be recycled or have a minimal impact on the environment when they reach the end of their useful life. Proper recycling or disposal methods should be followed to reduce waste and prevent pollution.

7. Sustainable Manufacturing:

Consider selecting wire pulleys from manufacturers that prioritize sustainable practices in their manufacturing processes. Manufacturers that utilize renewable energy sources, reduce waste generation, and employ environmentally friendly production methods contribute to a more sustainable supply chain.

By considering these environmental considerations and making conscious choices, it is possible to minimize the environmental impact associated with using wire pulleys in outdoor applications. This ensures the sustainable use of resources and helps protect the surrounding ecosystem.

What safety precautions should be taken when using wire pulleys for heavy lifting?

When using wire pulleys for heavy lifting, it is crucial to follow specific safety precautions to prevent accidents, injuries, and damage. Here are some important safety measures to consider:

1. Equipment Inspection:

Prior to using wire pulleys, conduct a thorough inspection of all equipment involved, including the pulleys, ropes or cables, hooks, and attachments. Check for any signs of wear, damage, or deterioration. Ensure that all components are in good working condition and properly rated for the intended load.

2. Load Capacity:

Never exceed the maximum load capacity specified by the manufacturer for the wire pulleys and associated equipment. Determine the weight of the load accurately and select the appropriate pulley with the necessary load rating to ensure safe lifting operations.

3. Proper Installation:

Follow the manufacturer’s instructions for the correct installation of wire pulleys. Ensure that they are securely attached to stable anchor points or support structures capable of withstanding the load. Use appropriate fittings, connectors, and fasteners that are compatible with the pulley and the lifting system.

4. Rigging Techniques:

Use proper rigging techniques to attach the load to the wire pulley. Ensure that the load is properly balanced and securely attached to prevent shifting, slipping, or falling during lifting. Use appropriate slings, hooks, or other rigging hardware that are suitable for the load and compatible with the pulley.

5. Personal Protective Equipment (PPE):

Wear the necessary personal protective equipment, such as gloves, safety glasses, and hard hats, when operating wire pulleys for heavy lifting. PPE helps protect against potential hazards, such as hand injuries, impact hazards, or falling objects.

6. Communication:

Establish clear communication protocols between the operator and other personnel involved in the lifting operation. Use standardized hand signals or communication devices to ensure effective communication and coordination during the lifting process.

7. Clear Work Area:

Clear the work area of any obstacles, debris, or personnel who are not directly involved in the lifting operation. Ensure that there is sufficient space for the load to move vertically or horizontally without interference. Mark off the work area and restrict access to unauthorized personnel.

8. Operator Training:

Ensure that operators are properly trained and competent in using wire pulleys for heavy lifting. Training should cover equipment operation, safe lifting practices, load calculation, inspection procedures, and emergency protocols. Regularly update training to stay informed about the latest safety guidelines and best practices.

9. Regular Maintenance:

Schedule regular maintenance and inspections of wire pulleys and lifting equipment. Follow the manufacturer’s recommendations for lubrication, cleaning, and replacement of worn or damaged components. Promptly address any identified issues or concerns.

10. Emergency Preparedness:

Develop and communicate emergency procedures in case of accidents, equipment failure, or unexpected incidents during heavy lifting operations. Ensure that personnel are familiar with emergency shutdown procedures, evacuation routes, and the location of emergency equipment, such as fire extinguishers or first aid kits.

By adhering to these safety precautions, you can minimize the risks associated with using wire pulleys for heavy lifting and promote a safe working environment for all personnel involved.

How do wire pulleys help in the lifting and moving of heavy loads?

Wire pulleys play a crucial role in lifting and moving heavy loads by utilizing the principles of mechanical advantage. They enable the application of less force to lift or move a heavy object by distributing the load over multiple ropes or cables. Here’s how wire pulleys help in the lifting and moving of heavy loads:

1. Multiplying Force:

Wire pulleys create a mechanical advantage by changing the direction of the force applied. When a rope or cable is threaded through a pulley system, the force required to lift the load is distributed between the sections of the rope connected to the pulley. By using multiple pulleys, the force can be further divided, resulting in a significant reduction in the force required to lift the load. This multiplication of force allows heavy loads to be lifted with less effort.

2. Changing Direction:

Wire pulleys also allow the force applied to be redirected, enabling lifting or moving in different directions. By changing the direction of the force, the operator can use a more convenient or advantageous angle for lifting the load. Wire pulleys provide flexibility in maneuvering heavy objects, especially when space or accessibility is limited.

3. Increasing Distance:

Another way wire pulleys assist in lifting heavy loads is by increasing the distance over which the force is applied. The length of the rope or cable used with the pulley system can be extended, allowing the operator to exert force over a larger distance. This increased distance results in a mechanical advantage, reducing the force required to lift the load.

4. Load Distribution:

Wire pulleys aid in load distribution, especially when multiple pulleys are used in combination. The weight of the load is distributed evenly across the ropes or cables connected to the pulleys. This balanced distribution minimizes stress on individual ropes or cables, ensuring that the load is lifted or moved safely and efficiently.

5. Control and Precision:

Wire pulleys provide control and precision in lifting and moving operations. The operator can adjust the tension in the ropes or cables by manipulating the pulleys, allowing for smooth and controlled lifting or movement of heavy objects. This level of control is crucial for tasks that require precise positioning or delicate handling of the load.

By employing wire pulleys in lifting and moving operations, the mechanical advantage gained significantly reduces the force required, making it easier and more efficient to handle heavy loads. Wire pulleys enable operators to overcome the limitations of their physical strength and perform tasks that would otherwise be impractical or impossible without the use of mechanical assistance.

editor by CX

2024-04-26