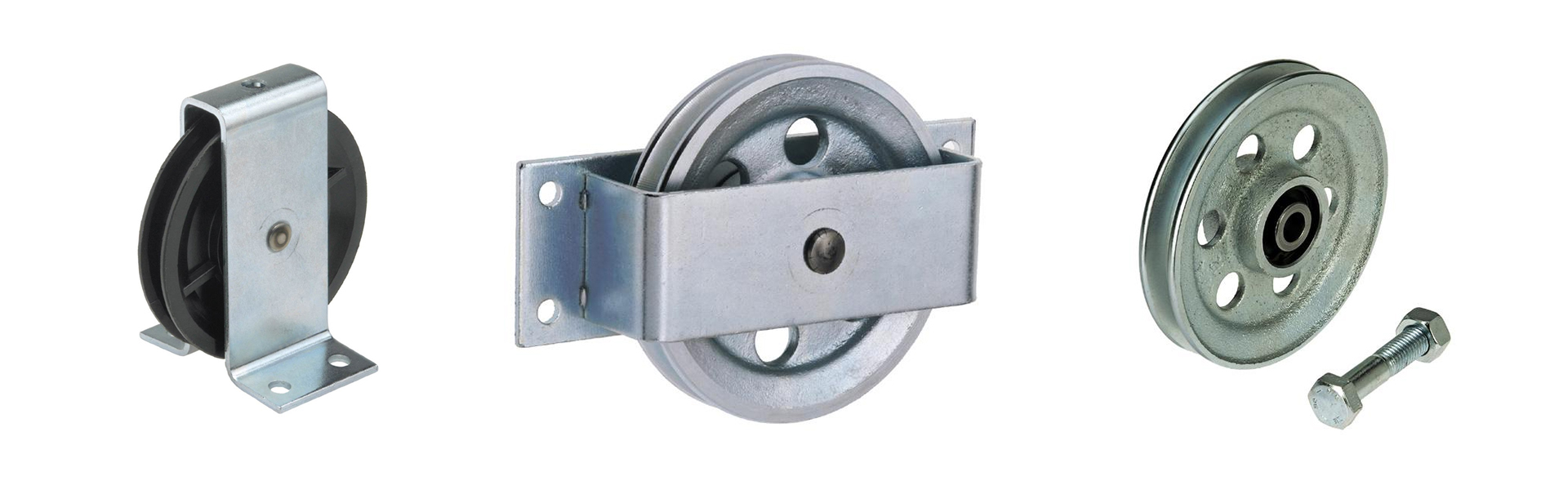

Product Description

Closed Type Lifting Wire Rope Steel Pulley with Three Sheaves

The Twin Swivel Block can fit multiple rope sizes ranging from 25mm to 50mm.This block body is made from grade 304 or 316

stainless steel and the removable sheave is made from grade 304 or 316 stainless steel for corrosion resistance and durability.

It is ideal for marine and industrial rigging applications.

About us

Haito stainless Co., Ltd. was founded in 1998.Specializing in the production of stainless

shackle,turnbuckle,terminal,screw and other metal products.Products of high quality,

fashionable, windely used in a variety of architecture, not only has the broad masses of the

domestic sales market,but also exported to Europe and the United States. Over the past few

years of production and management and exploration,Founder set up its own quality

management system. Passed the ISO9001:2008 quality system certification Founder always

implement the concept of customer value creation for customers tailored products to meet

the needs of different customers, and continuously provide customers with solutions and

technical problems. Further exploration and innovation, and excellence. Warmly welcome

you and opening up the boundaries of communication. We synchronize with your ideal

partner! we can produce many kinds of body for shackles, we export shackles to all over

the world. we can produce all sizes of shackles and can produce special shackles in

accordance with the customers’ requirements.

| We haito Stainless specializes in ss304 and ss316(L) Rigging, Pipe Fitting. |

| Contact me for futher detailed including the price. Waiting for your reply |

| The below is our more information: |

| *Experience: We are factory with 18 years export experience |

| *Process: Investment (Lost Wax) Casting & Forging, Machining, Mold Design |

| *Finishing: Mirror Polish |

| *Quality Control: Spectrometer Analysis & Load Testing Machines |

| *Management: ERP System |

| *Certificate: ISO 9001:2008 |

| *Service: Good after-sale team |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Boat, Yacht |

|---|---|

| Standard: | ASTM, GB, DIN, ANSI, JIS, ISO |

| Customized: | Non-Customized |

| Surface Treatment: | Polished |

| Material: | Stainless Steel 304/316 |

| Type: | Double Block |

| Samples: |

US$ 0.12/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is the role of wire pulleys in maintaining proper tension in cable-based systems?

Wire pulleys play a crucial role in maintaining proper tension in cable-based systems. They help distribute and manage the tension in the cables, ensuring smooth and efficient operation. Here’s a detailed explanation of the role of wire pulleys in maintaining proper tension:

1. Load Distribution:

Wire pulleys help distribute the load evenly across the cables in a system. As the cables pass over the pulleys, they change direction, which spreads the tension along the length of the cables. This prevents excessive stress and strain on any specific section of the cables, promoting uniform tension distribution.

2. Directional Change:

Wire pulleys facilitate changes in the direction of the cables. By redirecting the cables, pulleys allow for efficient routing and alignment, ensuring that the cables follow the desired path. This is particularly important in complex cable-based systems where cables need to navigate around obstacles or change directions at different points.

3. Tension Adjustment:

Wire pulleys enable tension adjustment in cable-based systems. By altering the position of the pulleys or changing the number of pulleys in the system, the tension in the cables can be adjusted as needed. This flexibility allows for fine-tuning the tension to achieve optimal performance and stability in the system.

4. Cable Retention:

Wire pulleys help retain the cables in their proper position. The grooved or contoured surface of the pulleys prevents the cables from slipping or coming off their intended path. This is particularly important in applications where maintaining cable alignment and position is critical for the system’s functionality and safety.

5. Friction Reduction:

Well-designed wire pulleys minimize friction between the cables and the pulley surfaces. Reduced friction helps to prevent excessive wear on the cables and reduces the energy required to move the cables. This results in smoother operation, lower power consumption, and less strain on the entire cable-based system.

6. Cable Protection:

Wire pulleys provide protection to the cables from external elements. The pulley’s smooth and rounded surfaces prevent sharp bends or kinks in the cables, reducing the risk of cable damage or fatigue. Additionally, pulleys can be designed with coatings or materials that offer resistance to corrosion, abrasion, or chemical exposure, further safeguarding the cables.

7. System Stability:

By maintaining proper tension in the cables, wire pulleys contribute to the overall stability of the cable-based system. Balanced tension prevents slack or excessive stretching of the cables, ensuring that they maintain the desired position and alignment. This stability is crucial for the system’s performance, reliability, and safety.

It is important to select wire pulleys that are appropriately sized, rated for the intended load, and compatible with the cable diameter and construction. Regular maintenance and inspection of the pulleys are also necessary to ensure they remain in good working condition and continue to perform their role effectively.

By utilizing properly designed and installed wire pulleys, cable-based systems can maintain optimal tension, promoting efficient operation, longevity of cables, and overall system reliability.

How do wire pulleys impact the efficiency and safety of material handling operations?

Wire pulleys play a significant role in improving the efficiency and safety of material handling operations. They offer several advantages that enhance the overall performance and mitigate potential risks. Here’s how wire pulleys impact efficiency and safety:

1. Mechanical Advantage:

Wire pulleys provide a mechanical advantage by distributing the load across multiple sheaves or changing the direction of force. This allows for easier lifting and moving of heavy objects, reducing the amount of effort required by the operator. By utilizing wire pulleys, operators can achieve greater efficiency in material handling tasks, as they can handle larger loads or operate with less physical exertion.

2. Load Distribution:

Wire pulleys distribute the load evenly across the sheaves, reducing stress on the lifting mechanism and the load itself. This helps prevent overloading of individual components and minimizes the risk of failure. By evenly distributing the load, wire pulleys contribute to the longevity and reliability of the material handling system, ensuring that it can consistently perform its intended function.

3. Precise Control:

Wire pulleys allow for precise control over the movement of the load. Operators can adjust the tension and direction of the rope or cable to ensure smooth and controlled handling of materials. This level of control is particularly important when working in confined spaces or when maneuvering delicate or valuable objects. Precise control enhances efficiency by minimizing the risk of accidents, damage, or product loss.

4. Versatility:

Wire pulleys are versatile and adaptable to different material handling operations. They can be integrated into various configurations, such as overhead crane systems, block and tackle setups, or portable rigging systems. This versatility allows wire pulleys to be utilized in diverse environments and applications, providing efficient solutions for a wide range of material handling tasks.

5. Safety Enhancements:

Wire pulleys contribute to safety in material handling operations in several ways:

– Reduced manual lifting: By utilizing wire pulleys, the need for manual lifting of heavy objects is minimized, reducing the risk of musculoskeletal injuries to operators.

– Controlled movement: The precise control offered by wire pulleys helps prevent sudden or unexpected movements of the load, reducing the likelihood of accidents, collisions, or falls.

– Load stabilization: Wire pulleys assist in stabilizing the load during lifting or movement, minimizing the risk of load shifts or instability that could lead to accidents or damage.

– Operator positioning: Wire pulleys enable operators to position themselves at a safe distance from the load, reducing the risk of being struck or trapped during material handling operations.

– Improved ergonomics: The mechanical advantage provided by wire pulleys reduces the physical strain on operators, promoting better ergonomics and reducing the risk of fatigue-related accidents or injuries.

– Enhanced visibility: Wire pulleys can be incorporated into systems that improve visibility during material handling operations, allowing operators to have a clear view of the load and its surroundings, thereby minimizing the risk of collisions or accidents.

By enhancing efficiency and safety, wire pulleys contribute to optimized material handling operations. Their ability to provide mechanical advantage, distribute loads, ensure precise control, and improve safety measures makes them valuable components in various industries and applications.

What is a wire pulley, and how is it used in various applications?

A wire pulley is a mechanical device that consists of a grooved wheel or sheave mounted on an axle or shaft. It is used to redirect or change the direction of a wire or cable as it passes over the pulley. Wire pulleys are designed to minimize friction and facilitate the smooth movement of the wire or cable. They find application in various industries and scenarios due to their versatility and efficiency.

1. Lifting and Rigging:

One of the primary applications of wire pulleys is in lifting and rigging operations. They are used in combination with wire ropes or cables to create mechanical advantage systems, allowing heavy loads to be lifted with less effort. Wire pulleys are commonly employed in construction sites, manufacturing facilities, and transportation industries for tasks such as hoisting equipment, moving materials, or rigging structures.

2. Conveyor Systems:

Wire pulleys are essential components in conveyor systems. They are used to guide and support conveyor belts or wire mesh belts, ensuring smooth movement and proper alignment of the transported goods or materials. Wire pulleys help maintain tension in the conveyor belt, preventing slippage and ensuring efficient material handling in industries such as mining, agriculture, and logistics.

3. Automotive and Transportation:

In the automotive and transportation sectors, wire pulleys are utilized in various applications. They are commonly found in vehicle engines, where they play a role in driving auxiliary components such as alternators, water pumps, and power steering systems through serpentine belt arrangements. Wire pulleys are also used in bicycle derailleurs, enabling smooth shifting of gears by guiding the movement of the derailleur cable.

4. Window Treatments and Shades:

Wire pulleys are employed in window treatment systems, such as blinds, shades, and curtains. They enable the smooth operation of the cords or cables used to raise, lower, or adjust the window coverings. Wire pulleys ensure that the cords move freely and remain properly tensioned, allowing users to easily control the amount of light and privacy in a room.

5. Exercise Equipment:

Wire pulleys are commonly found in exercise machines and gym equipment. They are used to create resistance or tension in cable-based systems, enabling users to perform various exercises. Wire pulleys in exercise equipment contribute to the smooth and controlled movement of the cables, providing resistance for strength training or facilitating range of motion for targeted muscle exercises.

6. Entertainment and Stage Systems:

Wire pulleys play a crucial role in entertainment and stage systems. They are utilized in theater rigging, concert productions, and other live performances to move scenery, lighting fixtures, and other equipment. Wire pulleys enable the precise and controlled movement of cables or ropes, allowing stage crews to perform scene changes, fly in props, or adjust lighting setups smoothly and safely.

7. DIY and Home Improvement:

Wire pulleys are often employed in various do-it-yourself (DIY) and home improvement projects. They can be used to create simple mechanical systems, such as garage door openers, homemade cranes, or manual lifting devices. Wire pulleys provide a cost-effective solution for redirecting or guiding wires or cables in DIY applications.

Wire pulleys come in different sizes, designs, and materials to suit specific applications. It’s important to select pulleys that match the intended load capacity, wire or cable diameter, and environmental conditions for optimal performance and safety.

Overall, wire pulleys are versatile devices used in a wide range of applications, including lifting and rigging, conveyor systems, automotive and transportation, window treatments, exercise equipment, entertainment and stage systems, as well as DIY and home improvement projects.

editor by CX

2024-05-09