Product Description

Product Description

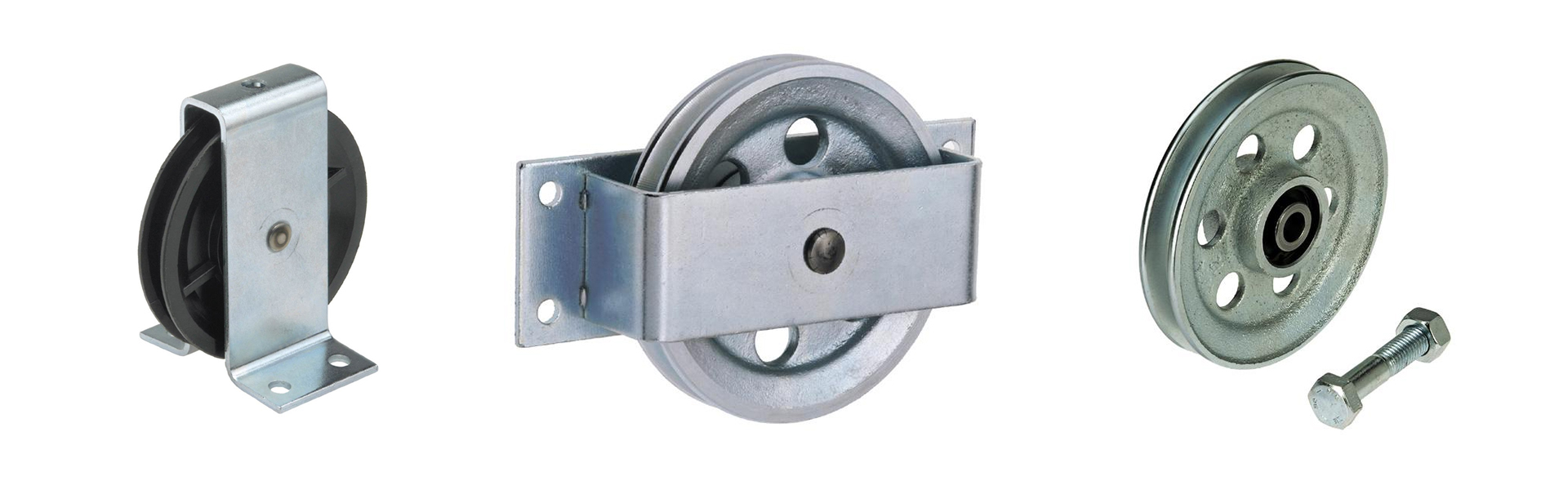

Container crane pulley block,

With high bearing capacity, high wear resistance and long service life

Sheave features:

1) Material: Q235B, Q345B, 35#, 45#, 60#, SSW-QR1, S45C

2) Groove surface quench: HRC45-55

3) Groove surface quench depth: 2mm-2.5mm

4) groove MT after heat treatment and welding line UT and MT

4) Max processing diameter: 2, 000mm

5) Short production cycle

It is used for crane equipment, port equipment, oil drilling rig and so on.

Detailed Photos

Production Profile

About Us

About Us

As a company of industries and trading integration with ISO 9001-2008 Certificate, HangZhou CHINAMFG Metallurgy Equipment Manufacturing Co., Ltd. Has been in manufacturing material handling equipment parts for many years, with professional experience.

Our Service:

If you are interested in any of our products, please contact me freely! Warmly Welcomed your visit to our factory in China, OEM service will be ok.

Application

Customer Visiting

Certifications

Packaging & Shipping

Services:

Best Services For You

1) We can provide OEM service and design for you

2) We can pack the goods according to your requirement

3) We test the quality of all products before delivery

4) We guarantee our reply in 24 hours of working day

5) We can communicate with you in different languages

6) High quality, best price, punctual shipment, good after-sale service will be guaranteed.

FAQ:

Q: What information should I provide if I want to order the products?

1) Product information: Quantity, specification

2) Delivery time required.

3) Shipping information: Company name, address, phone number, destination seaport/air port.

4) Forwarder’s contact details if there is any in China.

Q: How about your payment terms?

A: 30% -50%deposit, with the balance before delivery, we accept T/T and L/C at sight.

Q: Can I use our own logo?

A: Yes, we can produce by using your own logo if you need.

Q: How about sample & MOQ policy?

A: Welcome sample order. MOQ can be 1 set.

Q: What is your lead time for your goods?

A: Normally 30 days after confirmed order,

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Lifting |

|---|---|

| Material: | Steel |

| Lifting Capacity: | <1T |

| Fixed Form: | Welding Type |

| Shape: | Round |

| Certification: | ISO 9001 |

| Customization: |

Available

| Customized Request |

|---|

Can wire pulleys be customized or modified to suit specific applications?

Yes, wire pulleys can be customized or modified to suit specific applications. The ability to customize or modify wire pulleys allows for greater adaptability and efficiency in various lifting and pulling tasks. Here are some ways in which wire pulleys can be customized or modified:

1. Sheave Size and Configuration:

The sheave size and configuration can be customized to accommodate different rope or cable sizes and to achieve specific mechanical advantages. By adjusting the diameter, width, or number of sheaves, wire pulleys can be tailored to meet the load requirements and operational needs of a particular application.

2. Material Selection:

Wire pulleys can be customized by selecting different materials based on the application’s demands. For example, stainless steel or high-strength composites can be chosen to enhance corrosion resistance or reduce weight without compromising strength. The material selection can be tailored to withstand specific environmental conditions or to meet industry standards and regulations.

3. Bearing Type:

The type of bearings used in wire pulleys can be customized to suit different operating conditions and load requirements. For instance, sealed bearings can be employed to provide protection against dust and moisture, while high-load bearings can be chosen for heavy-duty applications. Customizing the bearing type ensures optimal performance and durability.

4. Coatings and Surface Treatments:

Wire pulleys can be customized with coatings or surface treatments to enhance their performance and longevity. Coatings such as zinc plating, powder coating, or specialized polymer coatings can be applied to protect against corrosion, abrasion, or chemical exposure. These coatings can be customized based on the specific environmental factors the pulleys will encounter.

5. Attachment Points and Accessories:

Wire pulleys can be modified by incorporating customized attachment points or accessories to facilitate integration into specific lifting or pulling systems. This may involve adding brackets, connectors, or hooks that are designed to work seamlessly with the equipment or rigging setup required for a particular application.

6. Specialized Features:

Wire pulleys can be customized with specialized features to meet unique application requirements. This could include the integration of sensors for load monitoring, anti-derailment devices for added safety, or locking mechanisms for secure positioning. Customized features enhance the functionality and safety of the wire pulleys in specific applications.

When considering customization or modification of wire pulleys, it is essential to consult with manufacturers, suppliers, or engineering experts who specialize in material handling equipment. They can provide guidance and expertise in assessing the feasibility of customization, determining the appropriate modifications, and ensuring compliance with safety standards and regulations.

By customizing or modifying wire pulleys, it is possible to optimize their performance, increase efficiency, and address the unique requirements of specific lifting and pulling applications.

Can wire pulleys be used in both stationary and mobile applications?

Yes, wire pulleys can be used in both stationary and mobile applications. They are versatile mechanical devices that can facilitate various lifting and moving tasks in different environments. Here’s how wire pulleys can be utilized in both stationary and mobile applications:

Stationary Applications:

In stationary applications, wire pulleys are often used in fixed locations where the pulley system remains in place. Some examples of stationary applications include:

– Construction sites: Wire pulleys are commonly used in construction projects for lifting heavy materials to different levels or moving them horizontally. They can be installed on cranes, scaffolding systems, or fixed structures to facilitate the movement of construction materials.

– Manufacturing facilities: Wire pulleys are employed in manufacturing plants for various tasks, such as lifting components during assembly processes or moving materials along conveyor systems. They can be integrated into production lines or workstations to enhance efficiency and streamline operations.

– Warehouses and distribution centers: Wire pulleys are utilized in warehouses and distribution centers for lifting and moving pallets, crates, or other heavy loads. They can be incorporated into overhead crane systems or used in conjunction with forklifts to optimize the handling of goods.

Mobile Applications:

In mobile applications, wire pulleys are designed to be portable and adaptable, allowing them to be easily transported and deployed in different locations. Some examples of mobile applications include:

– Rigging and hoisting: Wire pulleys are used in rigging and hoisting operations that require mobility. They can be employed in scenarios such as lifting equipment or materials onto elevated platforms, performing maintenance tasks on structures, or setting up temporary installations.

– Rescue and recovery operations: Wire pulleys are utilized in emergency situations, such as rescue and recovery operations. They can be utilized to create mechanical advantage systems for lifting or lowering individuals or objects in confined spaces, steep terrains, or other challenging environments.

– Outdoor activities and sports: Wire pulleys find applications in outdoor activities and sports that involve zip lines, rock climbing, or aerial maneuvers. They are used to create controlled movement along a cable or rope, providing participants with thrilling experiences while ensuring safety and stability.

Whether in stationary or mobile applications, wire pulleys offer advantages such as mechanical advantage, load distribution, and precise control. Their versatility makes them suitable for a wide range of tasks, and their adaptability allows them to be used in various settings and environments.

What is a wire pulley, and how is it used in various applications?

A wire pulley is a mechanical device that consists of a grooved wheel or sheave mounted on an axle or shaft. It is used to redirect or change the direction of a wire or cable as it passes over the pulley. Wire pulleys are designed to minimize friction and facilitate the smooth movement of the wire or cable. They find application in various industries and scenarios due to their versatility and efficiency.

1. Lifting and Rigging:

One of the primary applications of wire pulleys is in lifting and rigging operations. They are used in combination with wire ropes or cables to create mechanical advantage systems, allowing heavy loads to be lifted with less effort. Wire pulleys are commonly employed in construction sites, manufacturing facilities, and transportation industries for tasks such as hoisting equipment, moving materials, or rigging structures.

2. Conveyor Systems:

Wire pulleys are essential components in conveyor systems. They are used to guide and support conveyor belts or wire mesh belts, ensuring smooth movement and proper alignment of the transported goods or materials. Wire pulleys help maintain tension in the conveyor belt, preventing slippage and ensuring efficient material handling in industries such as mining, agriculture, and logistics.

3. Automotive and Transportation:

In the automotive and transportation sectors, wire pulleys are utilized in various applications. They are commonly found in vehicle engines, where they play a role in driving auxiliary components such as alternators, water pumps, and power steering systems through serpentine belt arrangements. Wire pulleys are also used in bicycle derailleurs, enabling smooth shifting of gears by guiding the movement of the derailleur cable.

4. Window Treatments and Shades:

Wire pulleys are employed in window treatment systems, such as blinds, shades, and curtains. They enable the smooth operation of the cords or cables used to raise, lower, or adjust the window coverings. Wire pulleys ensure that the cords move freely and remain properly tensioned, allowing users to easily control the amount of light and privacy in a room.

5. Exercise Equipment:

Wire pulleys are commonly found in exercise machines and gym equipment. They are used to create resistance or tension in cable-based systems, enabling users to perform various exercises. Wire pulleys in exercise equipment contribute to the smooth and controlled movement of the cables, providing resistance for strength training or facilitating range of motion for targeted muscle exercises.

6. Entertainment and Stage Systems:

Wire pulleys play a crucial role in entertainment and stage systems. They are utilized in theater rigging, concert productions, and other live performances to move scenery, lighting fixtures, and other equipment. Wire pulleys enable the precise and controlled movement of cables or ropes, allowing stage crews to perform scene changes, fly in props, or adjust lighting setups smoothly and safely.

7. DIY and Home Improvement:

Wire pulleys are often employed in various do-it-yourself (DIY) and home improvement projects. They can be used to create simple mechanical systems, such as garage door openers, homemade cranes, or manual lifting devices. Wire pulleys provide a cost-effective solution for redirecting or guiding wires or cables in DIY applications.

Wire pulleys come in different sizes, designs, and materials to suit specific applications. It’s important to select pulleys that match the intended load capacity, wire or cable diameter, and environmental conditions for optimal performance and safety.

Overall, wire pulleys are versatile devices used in a wide range of applications, including lifting and rigging, conveyor systems, automotive and transportation, window treatments, exercise equipment, entertainment and stage systems, as well as DIY and home improvement projects.

editor by CX

2024-04-19