Product Description

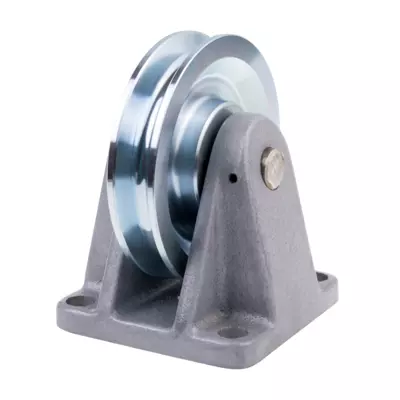

Wire drawing machine parts guide pulley with ceramic coating

Product Description

1. Processing Technology: Thermal Spray, Plasma Spray

2. Size: 91mm

3. Substrate Material: Aluminium Alloy

4. Coating Material: Cr2O3

5. Hardness: HV1100-1200

6. Roughness: <RA0.4μm

7. Property: Abrasion Resistance, Corrosion Resistance

8. Application: Wire Drawing Machine Parts

9. MOQ: 500 pieces

10. Packing: Carton and pallet

11. Shipping port: ZheJiang or HangZhou

12. Payment term: T/T( 30% deposit and balance before delivery)

13. Delivery time: About 30 – 60 days, according to order quantity

14. Free sample is available

The coating data rang we can make

| Range | Thickness | Hardness | Roughness |

| Minimum | 0.05mm | HV650 | RA<0.1μm |

| Maximum | 0.5mm | HV1300 | RA20μm |

Packaging & Shipping

Products are coated with PE film first. Then put them into the cartons. Third put the cartons on the pallets. At last coated with plastic film in order to waterproof.

Production Process

Thermal Spraying

Thermal spraying technology can strengthen the property of machine parts, such as abrasion resistance, corrosion resistance, anti-frication, high temperature resistance, heat insulation, oxidation resistance and anti-sticking and so on. Widely used in machinery, textile, printing, petroleum, metallurgy, electronics, auto industry, aerospace, power industry, light industry and other fields.

Company Profile

Established in 2001, Xihu (West Lake) Dis. CHINAMFG Technology Co.,Ltd. is a enterprise who specializes in development, promotion, production and processing of thermal spraying technology. Company is located in HangZhou City, ZHangZhoug Province. It is very near to ZheJiang , HangZhou and HangZhou, with superior geographical location and convenient transportation.

As a member of Thermal Spraying Specialized Committee of China Surface Engineering Association, CHINAMFG has been devoted to the R&D and promotion of thermal spraying technology and concentrated on the enterprise management for more than 15 years. Company owns a skilled, high efficiency and high quality R&D and production team, and has acquired many proprietary technology and patent certification. CHINAMFG has established a whole set of excellent and advanced thermal spraying technology through the introduction of domestic & foreign advanced equipments, such as plasma spraying equipment, HOVF equipment and electric arc spraying equipment, and varieties of finish machining techniques and testing methods. CHINAMFG has passed the quality management system certification ISO9001:2008. With excellent products and technical services, now our products are exported to Europe, the United States, Japan, ZheJiang and many other countries and regions.

CHINAMFG persists in the management philosophy of “quality, service and innovation “. Company supplies excellent products and reliable service for clients with continuous innovative technology. We look CHINAMFG to cooperating with you sincerely.

Certifications

Exhibition and Our Team

Our Advantages

1. All your inquiries will be replied within 12 hours.

2. Direct manufacturing factory for thermal spraying products provides competitive price.

3. Customized products are acceptable.

4. OEM is welcome, we will protect intellectual property of our customers.

5. Free samples are available

6. Strictly quality control and on-time delivery.

7. First-class after-sales services to the customers.

FAQ

Q. What are your main products?

A: We supply much kind of machine parts with thermal spraying coating and thermal spraying processing services.

Q: What is the MOQ?

A: The MOQis 100-500 pieces, depend on products.

Q: How about the sample policy?

A: The sample is free generally.Customers have to pay the express fee, such as DHL, TNT, UPS FedEx and so on.

Q: Which port is available?

A: The ZheJiang port and HangZhou port are very near to us.

Q: What is the payment term?

A: T/T(30% deposit in advance, 70% balance before delivery)

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | None |

|---|---|

| Warranty: | None |

| Condition: | New |

| Certification: | ISO9001:2015 ISO45001:2018 ISO14001:2015 |

| Customized: | Customized |

| Material: | Alloy |

| Customization: |

Available

| Customized Request |

|---|

What is the role of wire pulleys in maintaining proper tension in cable-based systems?

Wire pulleys play a crucial role in maintaining proper tension in cable-based systems. They help distribute and manage the tension in the cables, ensuring smooth and efficient operation. Here’s a detailed explanation of the role of wire pulleys in maintaining proper tension:

1. Load Distribution:

Wire pulleys help distribute the load evenly across the cables in a system. As the cables pass over the pulleys, they change direction, which spreads the tension along the length of the cables. This prevents excessive stress and strain on any specific section of the cables, promoting uniform tension distribution.

2. Directional Change:

Wire pulleys facilitate changes in the direction of the cables. By redirecting the cables, pulleys allow for efficient routing and alignment, ensuring that the cables follow the desired path. This is particularly important in complex cable-based systems where cables need to navigate around obstacles or change directions at different points.

3. Tension Adjustment:

Wire pulleys enable tension adjustment in cable-based systems. By altering the position of the pulleys or changing the number of pulleys in the system, the tension in the cables can be adjusted as needed. This flexibility allows for fine-tuning the tension to achieve optimal performance and stability in the system.

4. Cable Retention:

Wire pulleys help retain the cables in their proper position. The grooved or contoured surface of the pulleys prevents the cables from slipping or coming off their intended path. This is particularly important in applications where maintaining cable alignment and position is critical for the system’s functionality and safety.

5. Friction Reduction:

Well-designed wire pulleys minimize friction between the cables and the pulley surfaces. Reduced friction helps to prevent excessive wear on the cables and reduces the energy required to move the cables. This results in smoother operation, lower power consumption, and less strain on the entire cable-based system.

6. Cable Protection:

Wire pulleys provide protection to the cables from external elements. The pulley’s smooth and rounded surfaces prevent sharp bends or kinks in the cables, reducing the risk of cable damage or fatigue. Additionally, pulleys can be designed with coatings or materials that offer resistance to corrosion, abrasion, or chemical exposure, further safeguarding the cables.

7. System Stability:

By maintaining proper tension in the cables, wire pulleys contribute to the overall stability of the cable-based system. Balanced tension prevents slack or excessive stretching of the cables, ensuring that they maintain the desired position and alignment. This stability is crucial for the system’s performance, reliability, and safety.

It is important to select wire pulleys that are appropriately sized, rated for the intended load, and compatible with the cable diameter and construction. Regular maintenance and inspection of the pulleys are also necessary to ensure they remain in good working condition and continue to perform their role effectively.

By utilizing properly designed and installed wire pulleys, cable-based systems can maintain optimal tension, promoting efficient operation, longevity of cables, and overall system reliability.

Can wire pulleys be used in both stationary and mobile applications?

Yes, wire pulleys can be used in both stationary and mobile applications. They are versatile mechanical devices that can facilitate various lifting and moving tasks in different environments. Here’s how wire pulleys can be utilized in both stationary and mobile applications:

Stationary Applications:

In stationary applications, wire pulleys are often used in fixed locations where the pulley system remains in place. Some examples of stationary applications include:

– Construction sites: Wire pulleys are commonly used in construction projects for lifting heavy materials to different levels or moving them horizontally. They can be installed on cranes, scaffolding systems, or fixed structures to facilitate the movement of construction materials.

– Manufacturing facilities: Wire pulleys are employed in manufacturing plants for various tasks, such as lifting components during assembly processes or moving materials along conveyor systems. They can be integrated into production lines or workstations to enhance efficiency and streamline operations.

– Warehouses and distribution centers: Wire pulleys are utilized in warehouses and distribution centers for lifting and moving pallets, crates, or other heavy loads. They can be incorporated into overhead crane systems or used in conjunction with forklifts to optimize the handling of goods.

Mobile Applications:

In mobile applications, wire pulleys are designed to be portable and adaptable, allowing them to be easily transported and deployed in different locations. Some examples of mobile applications include:

– Rigging and hoisting: Wire pulleys are used in rigging and hoisting operations that require mobility. They can be employed in scenarios such as lifting equipment or materials onto elevated platforms, performing maintenance tasks on structures, or setting up temporary installations.

– Rescue and recovery operations: Wire pulleys are utilized in emergency situations, such as rescue and recovery operations. They can be utilized to create mechanical advantage systems for lifting or lowering individuals or objects in confined spaces, steep terrains, or other challenging environments.

– Outdoor activities and sports: Wire pulleys find applications in outdoor activities and sports that involve zip lines, rock climbing, or aerial maneuvers. They are used to create controlled movement along a cable or rope, providing participants with thrilling experiences while ensuring safety and stability.

Whether in stationary or mobile applications, wire pulleys offer advantages such as mechanical advantage, load distribution, and precise control. Their versatility makes them suitable for a wide range of tasks, and their adaptability allows them to be used in various settings and environments.

In which industries and scenarios are wire pulleys commonly employed?

Wire pulleys find application in various industries and scenarios due to their versatility and efficiency. Here are some common industries and scenarios where wire pulleys are commonly employed:

1. Lifting and Rigging:

Wire pulleys are extensively used in lifting and rigging operations. They are employed in construction sites, manufacturing facilities, and transportation industries for tasks such as hoisting heavy equipment, moving materials, or rigging structures. Wire pulleys, in combination with wire ropes or cables, create mechanical advantage systems that allow heavy loads to be lifted with less effort.

2. Conveyor Systems:

Wire pulleys are essential components in conveyor systems. They are used to guide and support conveyor belts or wire mesh belts, ensuring the smooth movement and proper alignment of transported goods or materials. Wire pulleys help maintain tension in the conveyor belt, preventing slippage and ensuring efficient material handling in industries such as mining, agriculture, and logistics.

3. Automotive and Transportation:

Wire pulleys are utilized in various applications in the automotive and transportation sectors. They are commonly found in vehicle engines, where they play a role in driving auxiliary components such as alternators, water pumps, and power steering systems through serpentine belt arrangements. Wire pulleys are also used in bicycle derailleurs, enabling smooth shifting of gears by guiding the movement of the derailleur cable.

4. Window Treatments and Shades:

Wire pulleys are employed in window treatment systems, such as blinds, shades, and curtains. They enable the smooth operation of the cords or cables used to raise, lower, or adjust the window coverings. Wire pulleys ensure that the cords move freely and remain properly tensioned, allowing users to easily control the amount of light and privacy in a room.

5. Exercise Equipment:

Wire pulleys are commonly found in exercise machines and gym equipment. They are used to create resistance or tension in cable-based systems, enabling users to perform various exercises. Wire pulleys in exercise equipment contribute to the smooth and controlled movement of the cables, providing resistance for strength training or facilitating the range of motion for targeted muscle exercises.

6. Entertainment and Stage Systems:

Wire pulleys play a crucial role in entertainment and stage systems. They are utilized in theater rigging, concert productions, and other live performances to move scenery, lighting fixtures, and other equipment. Wire pulleys enable the precise and controlled movement of cables or ropes, allowing stage crews to perform scene changes, fly in props, or adjust lighting setups smoothly and safely.

7. DIY and Home Improvement:

Wire pulleys are often employed in various do-it-yourself (DIY) and home improvement projects. They can be used to create simple mechanical systems, such as garage door openers, homemade cranes, or manual lifting devices. Wire pulleys provide a cost-effective solution for redirecting or guiding wires or cables in DIY applications.

These are just a few examples of the industries and scenarios where wire pulleys are commonly employed. Wire pulleys offer versatility and efficiency, making them valuable tools in numerous applications.

editor by CX

2024-04-17